In general, when you plan to prepare NPK fertilizer, there are two methods that are popular with NPK fertilizer manufactures. They are NPK fertilizer granulation line and NPK fertilizer blending system. The former can help you turn powder chemical fertilizer into NPK fertilizer pellets. While the latter can process granular chemical fertilizer into NPK fertilizer you need. You can choose one from them according to your material, budget, factory area, etc. For example, on 2rd April, a customer from USA wanted to make 20 10 10 NPK granular fertilizer. After discussing the details, we recommended him the suitable solutions. And we can can provide you with customized NPK fertilizer plant design.

How to Make Powder Materials into NPK Fertilizer Granules?

Then American Customer wanted to have a 20 10 10 NPK fertilizer Manufacturing line. If he plans to make more profits, our NPK fertilizer granulation line is the best choice for you. Then what is the design of 20 10 10 NPK fertilizer granulation line?

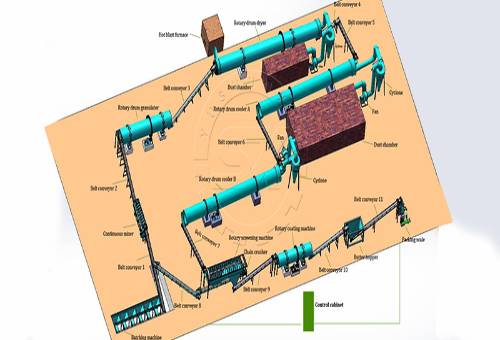

During this process, the materials will go through multiple processes. Including batching, crushing, mixing, granulating, drying, cooling, screening, coating and packaging. They will make powdery materials become the high quality granular NPK fertilizer you need. Accurate batching is the basis of strictly producing NPK fertilizer according to your 20 10 10. Crushing and mixing contribute to the production of uniform NPK fertilizer. Granulating, drying, cooling provide it with a lower possibility of sticking. Coating can improve its utilization and appearance.

How to Prepare NPK Fertilizer with NPK Fertilizer Blending Plant?

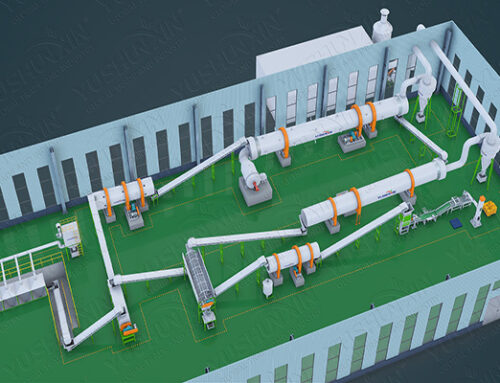

Customer from USA also wanted to have an economical NPK fertilizer Production line. For this, we recommended him to purchase NPK fertilizer blending line. This plant can also help him to make 20 10 10 NPK fertilizer. But how does it work to process them into required NPK fertilizer?

What Equipment can Improve the Quality of 20:10:10 NPK Fertilizer?

Besides the fertlizer equipment mentioned above, there are many other fertlizer processing machines for your choice. They can help you produce better 20:10:10 NPK fertilizer.

Screening Machine for Granules Classification

After cooling, you will find that not all NPK fertilizer pellets meet your requirements. You need to screen out the qualified products and make unqualified granules go through granulating again. At that time, rotary screening machine can help you finish the task easily.

Coating Equipment for NPK Fertilizer Pellets

lf you want to further improve your npk fertilizer quality, coating is an excellent option for you. It will add a protective film to the surface of the NPK granules. The protective film can prevent sticking and nutrient loss. So the npk fertilizer pellet will become easier to transport and store. For this,we can provide you with drum coating machine.

How Much Does SX 20:10:10 NPK Fertilizer Plant Cost?

Generally speaking, the price of NPK fertilizer making line is not fixed. Because it is related to NPK fertlizer making scale, confguration, equipment types, etc. From the data of our past cases, the cost of an 20:10:10 NPK fertilizer preparation system is as follows:

How to Choose Materials for your 20 10 10 NPK Fertilizer Manufacturing?

For NPK fertilizer preparation, the first step is material selection. For this, there is a item we let American customer need to focus on when choosing the materials for NPK fertilizer production.

NPK fertilizer making materials types

Why Do you Want to Make 20 10 10 NPK Fertilizer?

Now many fertilizer manufacturers want to make NPK fertilizer. Because different proportions of nitrogen, phosphorus and potassium supply different nutrients to crops. Like a client from USA wanted to make 20 10 10 NPK fertilizer, so what benefits can provide you when processing NPK fertilizer?