Because of rich nutrients contained, cow manure is an ideal material for organic fertilizer production. This is not only beneficial for dairy farm manure management but also helps you make more profits. But turning cattle manure into organic fertilizer pellets needs a more complicated procedure and a larger investment. Can we prepare cow dung fertilizer in a simpler and more economical way? Of course. Processing cow farm waste into powdery fertilizer!

On 25th March 2023, a customer from Lebanon wanted to manufacture cow dung powdery fertilizer. For this, SX can provide him with various cow dung powder making machines for his choice. We can help him finish cattle waste fertilizer manufacturing quickly and smoothly.

How to Choose a Suitable Crusher for Cow Dung Powder Production?

Lebanese customer thought the manure shredder plays an important role in making cattle waste powder fertilizer. So which pulverizer is suitable for your cattle farm waste disposal? What is the difference between semi-wet materials grinder and new type vertical shredder? You can get the answer here.

Semi-Wet Materials Grinder – Finer Powder

If you want to crush cow dung into finer powder, we recommend you purchase our semi-wet materials pulverizer. It adopts a double-stage crushing system. That is, the cattle waste material first is crushed into small particles and then crushed into fine powder. And the final crushing granularity is about 50 meshes. Generally, the nutrients in this kind of powder fertilizer is easier to be absorbed by plants. Moreover, it can process 1-8 tons of powder fertilizer per hour. So it can fully meet your requirements of small-medium scale cow manure fertilizer preparation.

New Type Vertical Shredder – Large Capacity

Is there a larger capacity cow dung powder making machine? The answer must be yes. You can choose SX new type vertical shredder, which has an output of 3-15 t/h. Using it, you can start your large scale dairy manure powder manufacturing successfully. However, processing so much cattle dung, does vertical grinder have designs for blocking prevention? Of course. On the one hand, the crushing blades adopt special steel which has high strength. This means this machine can grind manure into small size powder effectively. On the other hand, there is no sieve mesh inside. So crushed cow dung can be discharged without blocking.

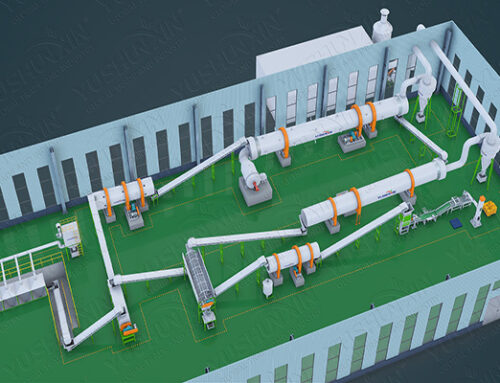

What Other Equipment you need in Cattle Manure Powder Fertilizer Manufacturing?

Besides the equipment mentioned above, the customer from Lebanon wanted to know are there other organic fertilizer machines needed for preparing powder fertilizer with cow dung? Before processing cattle manure with powder fertilizer production line, there are two processes you must pay attention to.

Moisture content plays an important role in manure fertilizer making, whether you plan to make it into granular or powder. Generally speaking, fresh cow manure has high water content, which is not suitable for starting organic fertilizer production directly. Because when the moisture content of material is higher than 65%,the fermentation effect will be reduced. And it also will influence the quality of final fertilizer. For this, SX dewatering machine can help you a lot. It can remove excessive water from animal manure and reduce the moisture content of cattle manure to 30%.

Composting is a necessary process for organic waste fertilizer manufacturing. Of course, the same as the cattle manure powdery organic fertilizer making line in Lebanon. It is a process which makes use of high temperature to kill harmful bacteria, pest eggs and grass seeds in cow waste. So the cow manure fertilizer produced by powdery fertilizer making system can supply nutrients for crop growth without harmfulness. For this, SX especially designs various machines for fermentation for your choice. They can help you finish the harmless process of chicken dung easily and quickly. And you can choose one according to your needs

What is the Price of Cattle Waste Powder Production System?

SX powder fertilizer making line is an ideal choice for turning cow manure into organic fertilizer at a low cost. Then Lebanese customer wanted to know what is the precise quote of cow dung powder making system? Usually, the cost of cow dung powder manufacturing project is not fixed. It is related to many factors, including capacity, fertilizer equipment manufacturer, etc.