How to Dispose of Biogas Residues as the Raw Material to Produce 2TPH Fertilizer?

The moisture in biogas residues is very high, if it is not dehydrated and directly made into fertilizer, it is difficult to condense into agglomerates. So you can use a solid-liquid separator for dehydration. Its output is 2-3t/h, just suitable for producing 2t/h organic fertilizer. You can prepare the dehydrated biogas residues for later production.

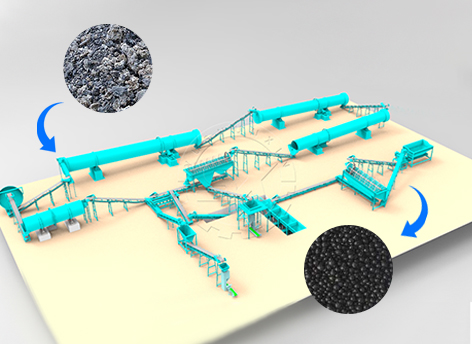

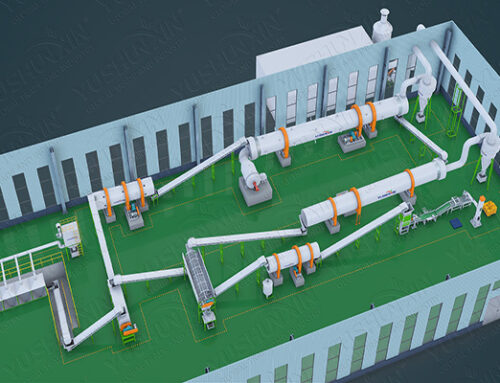

2TPH Organic Fertilizer Pellets Production for Biogas Residues

Reasonable utilization of biogas residue can bring you the maximum benefit. But how to turn these biogas residues into treasures? You can use this biogas residue to produce organic fertilizer. Because the content of organic matter in these biogas residues is very high, which is a good raw material for the production of organic fertilizers. After dehydrating the biogas residues as mentioned above, you need to compost them to prepare for subsequent production. Crush and stir them all after composting, so that mixing the organic matter fully and uniform in size. Next you can granulate. According to the output of 2t/h, you can choose the disc granulator. The granulation rate of this equipment can reach 93%, which can meet your granulation needs. Finally, the prepared granules you can dry and cool before being packaged.

How to Get Biogas Residue Pellets of Uniform Size?