Double roller press granulation plant is widely used in compound and organic fertilizer production. It can turn powder material into granules at a lower cost. Because it adopts dry granulation method, which makes compound and organic fertilizer particles only by physical extrusion force. And there is nearly no water involved in complex and organic fertilizer making process. So you don’t need to spend on fertilizer pellets drying and cooling. In addition, it also has characteristics of less energy consumption, high granulation rate, easy operation, etc. This is the reason why more and more fertilizer choose double roller granulation line for their fertilizer plant. Moreover, SX can provide you with roller extrusion granulation lines with different capacities and design layout according to your actual conditions. If you are interested in it, you can contact us at any time.

- 1

Capacity: 1-3 t/h

- 2

Equipment material: Carbon steel Q235/ Alloy

- 3

Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- 4

Design: (Composter, dewatering machine) batching machine, crusher, mixer, granulator, screener and packaging equipment, etc.

- 5

Application: organic fertilizer or compound fertilizer

How does double roller granulation plant to process compound fertilizer?

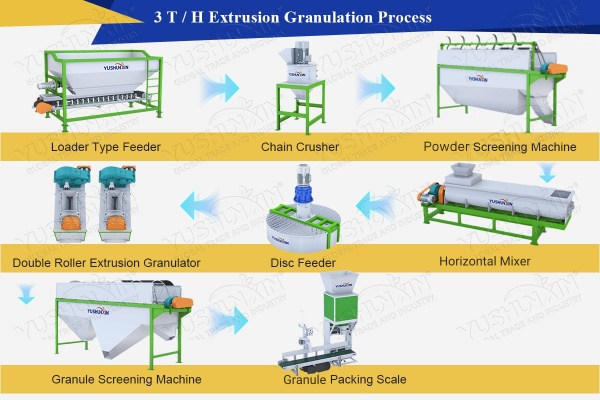

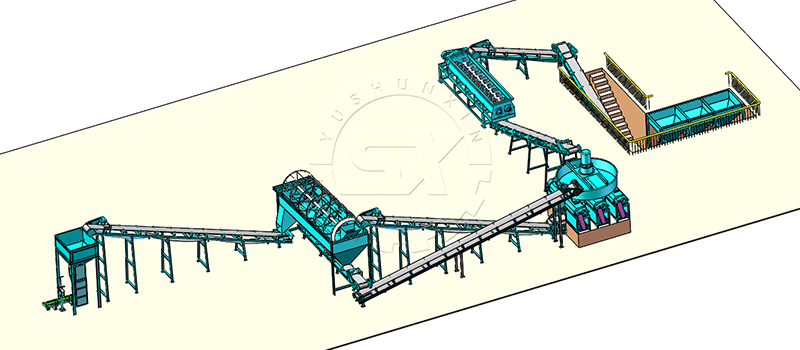

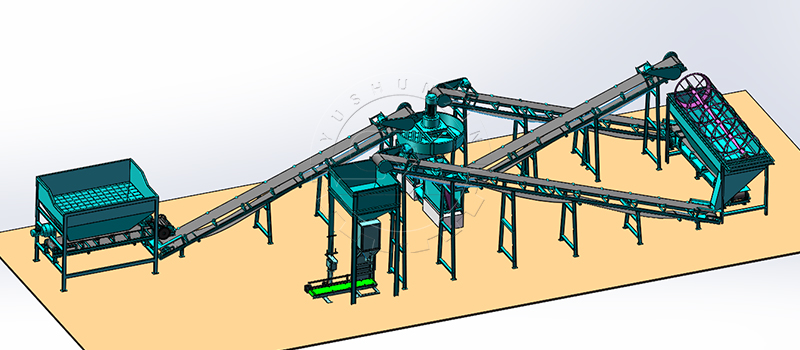

If you want to buy a fertilizer making line, it is necessary to know what equipment is needed in it. In general, a complete double roller granulation line consists of five stages, six types of fertilizer processing machines as follows:

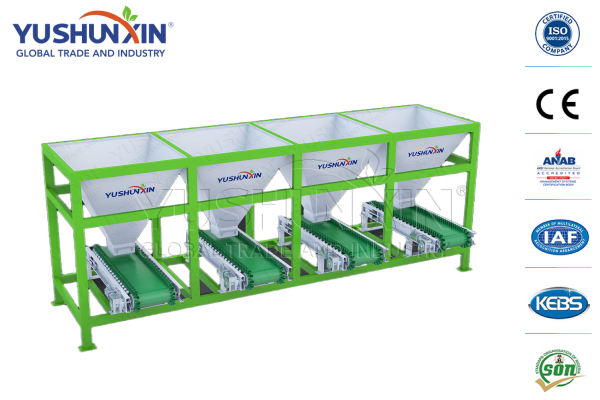

Batching machine

During this process, you need to feed the various chemical powder according to required formula. The difference in material proportion is the reason why your fertilizer is different from others. So you need to focus on the accuracy of batching. In this case, SX automatic batching equipment is an optimal option for you. It is equipped with electronic scale and PID regulation and alarm system, which greatly contributes to improving batching accuracy.

Mixer

Mixer can help you mingle various chemical materials evenly to prevent nutrients imbalance. And for powdery blending, we can provide you with a variety of fertilizer mixers. You can choose a suitable one according to your needs. Then we have three type of mixers for your choice: horizontal mixer, double shafts horizontal mixer and single shaft blending equipment.

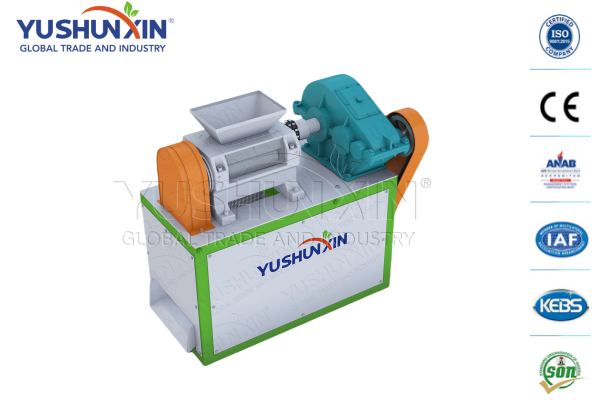

Roller granulation

This is the most important step in fertilizer roller extrusion granulation line. In this process, the mixed material will be granulated by extrusion force between two rollers. After pressing granulating, compound fertilizer is more convenient for transport and storage. Because granular fertilizer can prevent nutrients layering during transport and storage. Here, we design double roller granulators with different capacities for your choice.

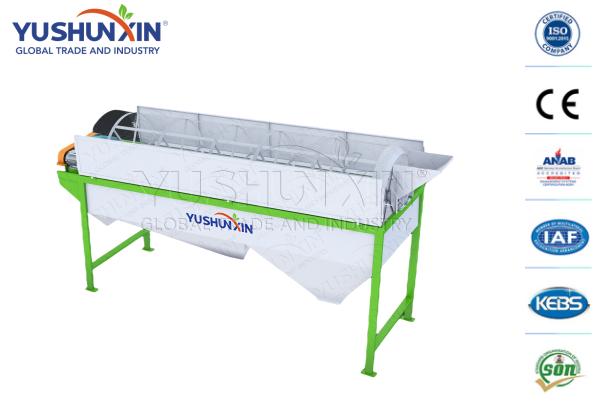

Rotary granules screener

After granulation, in order to ensure the quality of compound fertilizer pellets you produce, it is advisable to sieve them with rotary screener. Which can separator required size compound granules from others. Then you can transport qualified granular compound fertilizer to the next process.

Packaging

Fertilizer packaging is the final stage of double roller pelleting line. In this stage, automatic packaging scale will bag granular complex fertilizer in 20kg/bag or 50 kg/bag in a short time. This is beneficial for transport and storage. And various packing capacities can meet different requirements for fertilizer suppliers.

What other machines can make organic fertilizer in double roller press granulation plant?

In addition to the equipment mentioned above, what other equipment can help produce organic fertilizer granules?

Screw dewatering machine

For removing excessive moisture, screw dehydrator is your best choice. It adopts a stainless steel sieve with 0.3-0.5 mm holes, which can help you separate solids from excrement of livestock quickly. After dewatering, the water content of manure can be reduced to 30%-40%, which is more suitable for organic fertilizer making.

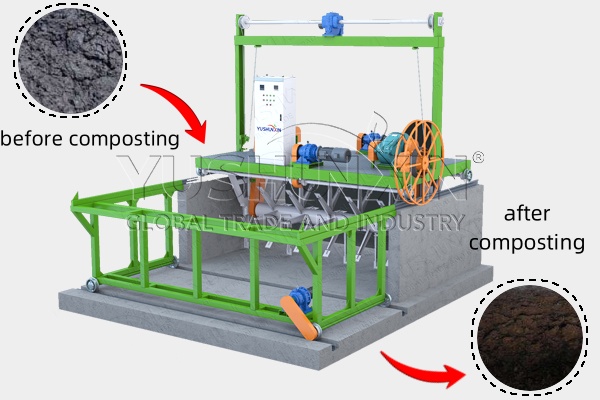

Composting machine

Composting plays an important role in removing harmful substances from manure. For fertilizer fermentation, there are 4 types of fertilizer composting machines for your choice. For starting small scale composting in fermentation trench, we recommend you choose groove type composter. When you plan to start composting on the ground directly, you can buy windrow compost turner. In addition, if you want to finish composting of organic waste faster, the in-vessel fermentation tank is your optimal option. Finally, for large scale composting, wheel type composter is more suitable for you.

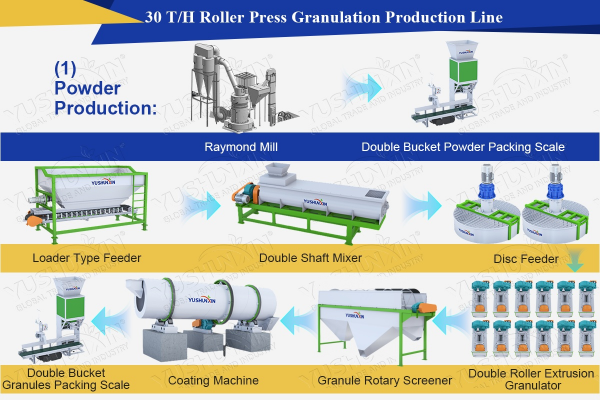

Top 2 different scale of double roller pelleting lines in YUSHUNXIN

The capacity of double roller granulation line must be an item most fertilizer manufacturers pay attention to. Then what is the capacity of fertilizer making line? The answer is that it can produce fertilizer not only in a small scale but also in a large scale. Different capacity requirements have different project designs. Generally speaking, it can be divided into two cases:

How to buy double roller press granulation plant at a favorable price?

Price of this roller pressing granulation line also must be an item you focus on. And a complete SX double roller granulation line will cost $ 25,000-$ 60,000. Then how to buy it in an economical way? There are three tips for your reference.

How to prolong the service life of the roller granulator production line?

The use of the double roller press granulator production line has a certain life span. If you do not find and repaire in time, it will greatly reduce the production efficiency of the entire production line. Below I will detail possible problems and solutions.

Therefore, improving the service life of related equipment will increase the service life of the entire production line.

Technology of roller compaction granulation production line

The double-roll granulation production line involves two aspects of process skills, please refer to the following introduction for details.

These two processes play a huge role in the production line, making the quality of the produced particles better.

What are the benefits of using potassium sulfate as a raw material for granulation in a double-roll extrusion granulation line?

Quotation for roller granulator production line

What customers care most about the production line is the price. But how to get a quotation for a double-roll granulation line? It is necessary to start with raw materials, output and equipment. Understand these clearly and get relevant data to determine the price.

The above is the quotation of the entire double-roll granulation production line. If you need, you can come to consult.