Chicken poop is very common in our daily life. But how to use them and maximize their advantages is what we need to consider. There are many ways to dispose of chicken manure. The process method involved is worth studying. The effects of chicken manure processed by different methods are also different. In order to make better use of chicken poop, I will help you answer your questions in terms of processing methods and equipment used.

A Surprising Technology to Help You Dispose of Chicken Poop

The commonly used process for chicken manure treatment is aerobic fermentation. Adopting this process method makes the chicken poop compost warm up quickly and the fermentation temperature is high. Shortening the cycle of chicken manure decomposing greatly.The equipment suitable for this process method is also different, and I will introduce them one by one below.

Groove Type Compost Turner for Chicken Poop Disposal

First of all, you need to build a fermentation groove with a width of 6 meters, a depth of 1.5 meters, and a length of 50-100 meters. Then you put the configured chicken manure material into the groove. The material is preliminarily crushed and stirred by a trough-type composting machine. Make the material fully exposed to oxygen to achieve the fermentation effect.

Windrow Compost Machine to Deal With Chicken Manure

Strip stack fermentation equipment includes crawler type composting machine and moving compost turner. For both of these, you need to stack the materials in long strips in advance. Each row of materials is 4-6 m wide and about 2 m high. And the length is determined according to the actual situation. You can install ventilation pipes under the material pile to supplement your material oxygen.Coupled with the continuous composting of the equipment, increasing the contact surface between the material and the air. Ultimately achieving perfect fermentation.

How to Turn Chicken Manure into Fertilizer with Corresponding Equipment?

Fermentation Method to Make Bio Fertilizer for Disposing of Chicken Poop

As long as you handle chicken manure correctly, you can turn chicken manure into treasure to produce bio-organic fertilizer. Let me introduce its fermentation steps for you.

When you make a chicken manure fermentation pile, you can’t make it too small or too short. Too small will affect fermentation. So you need to control the height at about 1.5 meters, the width at about 2 meters, and the length at more than 2 to 4 meters. This kind of fermentation effect is better.

Chicken manure organic fertilizer biological starter is an aerobic microorganism. Therefore, you should increase oxygen supply measures during the fermentation process, and it is advisable to mix well, turn over frequently, and ventilate. Otherwise, your material will affect the fermentation effect due to anaerobic fermentation.

Generally, there will be 2 to 3 times of high temperature above 65°C during the fermentation process. Turn over 2 to 3 times to complete the fermentation. Normally, the fermentation can be completed in about a week, so that the materials can be completely deodorized, fermented and decomposed, sterilized and killed.

Actionable Tips on Dried Chicken Manure

If you are not dispose of fresh chicken manure, it will cause a series of problems. Especially in summer, the smell can be very strong. And there are a lot of bacteria and viruses in chicken manure, which is also the main route of disease transmission. So it is imminent to deal with chicken manure.

Manure dewatering Machine for Disposal of Chicken Poop

Wet chicken manure is not convenient for storage for subsequent operations. Therefore, in order to better carry out subsequent process such as fertilizer making and sales, you can prepare chicken manure for dehydration first. Through the manure dehydrator, you can drain the excess water in the chicken manure, so that it can be made into dry chicken manure later.

Manure dryer to Treat with Chicken Poop

To further reduce the moisture content of chicken manure, you can use a dryer. With the manure dryer, you can dry manure with a water content of up to 70%-80% to a water content of 13%. In addition, we can also customize the dryer according to your needs.

Pre-treatment of chicken manure can facilitate subsequent operations. You can use the above method as a reference.

Traditional Fermentation VS Microbial Rapid Fermentation

Traditional fermentation takes a long time, usually 1 to 3 months.And the surrounding stench is unpleasant, and there are a lot of mosquitoes and flies. Environmental pollution is very serious. When the chicken manure is relatively wet, auxiliary materials need to be added, which requires more labor.

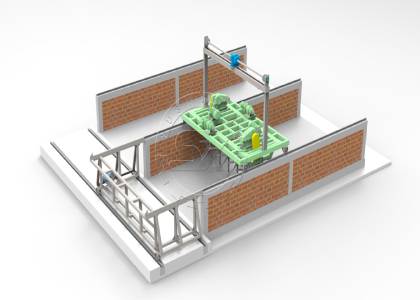

Microbial rapid fermentation is to use organic fertilizer fermenter to ferment and decompose chicken manure. By adding biological fermentation bacteria and combining the heat energy of the equipment itself for decomposing. This fermenter can automatically adjust the moisture according to the state of the material. And according to the stirring device in the tank, the material fermentation is more uniform and thorough. In addition, the whole process is closed and treated, which is environmentally friendly and hygienic and has a strong deodorizing function.

From the above point of view, compared with the traditional fermentation mode, the organic fertilizer fermentation tank should be more suitable for you.