Compound fertilizer production line includes two types of fertilizer production line.The first one is BB fertilizer production plant. The second one is NPK fertilizer production project. From the following, you can know specific information about the compound fertilizer production line. And we can help you design a production line that suits you. In particular, there is no need to worry about pre-sales and after-sales services, we will prepare for you. Therefore, don’t hesitate, you can rest assured to buy SX’s equipment.

Different Types of Compound Fertilizer Production Line for Sale

Compound Fertilizer Equipment

NPK Fertilizer Manufacturing Line Cost

Phosphate Fertilizer Granulation Plant

BB Fertilizer Production Line

NPK Fertilizer Production Line

How to Start 150,000 T/Y Compound Fertilizer Production Line?

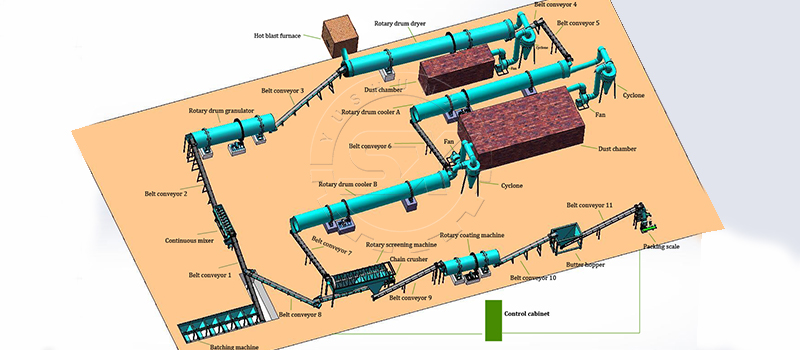

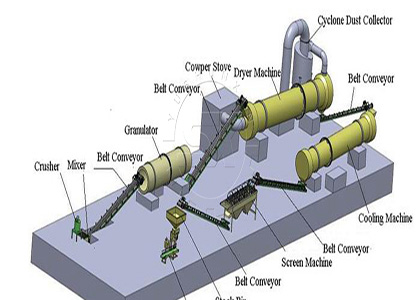

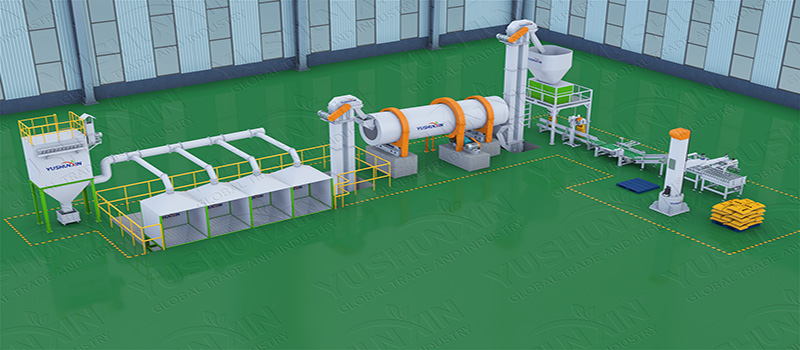

In general, as a professional fertilizer equipment factory, SX will design fertilizer production project according to your actual conditions. In this process, capacity is an item we must consider. Then what equipment is used in a 150,000 t/y compound fertilizer production line? Commonly, it is advisable to keep fertilizer preparation line running 2 shifts a day and 10 hours a shift. So you need to buy compound fertilizer machines with a capacity of 20 t/h. For this, we recommend you purchase the following equipment:

Batching Machine

Generally, SX fertilizer batching machine adopts electric weighting technology. So it can strictly feed various raw materials according to the required proportion. In this way, you can produce compound fertilizer with richer nutrients and higher quality.

SXFLF-10oo New Type Vertical Crusher

Because new type vertical ferilizer shredder employs special steel crushing blades. It have a longer service life and can grind batching material into fine powder quickly. In addition, we especially use polypropylene plate as lining and there is no screen mesh. Therefore, it has strong applications for high moisture materials and is not easy to block.

Powder Screening Equipment

In order to prepare better compound fertilizer, screening is necessary. Powder rotary screener can help you separate waste and large particles from fine batching powder. Then the waste (stones, cigarette butts, etc) will be discharged and large particles will be returned to shred again. This is beneficial for improving the purity of final fertilizer product and reducing material waste.

Single Shaft Horizontal Mixer

This mixer processes compound fertilizer with a group of double helical ribbon type blade. It can blend various organic materials evenly. This can ensure you produce fertilizer with balanced nutrients.

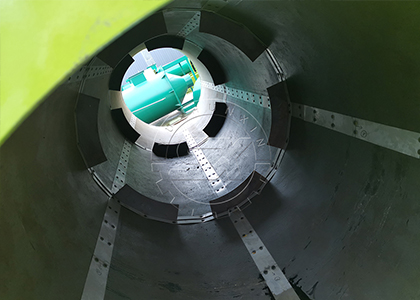

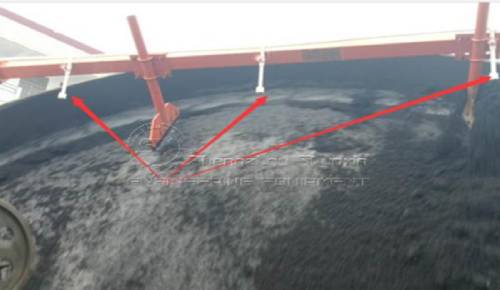

SXZGZ-32I0 Rotary Drum Pelletizer

For large scale organic fertilizer granulation, the best hot selling equipment is rotary drum pelletizer. On the one hand, it has a large capacity, which means it can granulate more batching material into pellets. Therefore, you can finish large scale organic fertilizer granules manufacturing more quickly. On the other hand, it has low energy consumption. The power of SXZGZ-3210 rotary drum pelletizer, which can process 15-30 tons of organic fertilizer pellets per hour (100,000 ton/year and more), is only 37 kw.

SXGS-2o8o Rotary Screener

In order to improve the purity of final compound fertilizer granules, it is advisable to screen it after granulation. For this, SXGS-2080 rotary screener is an excellent option. It can separate the required size compound fertilizer pellets from small or large particles. Then you can return unqualified fertilizer pellets to re-crush and re-granulate. So you will complete large scale compound fertilizer production with nearly no material waste.

SXHG-2424 Rotary Dryer and SXLQ-2424 Rotary Cooler

Because rotary drum granulator adopts wet granulation method, which uses liquid as binder to make batching material powder into pellets. The water content of produced compound fertilizer pellets is about 15%-20%. However, in order to make fertilizer more convenient for transport, store and use, it is necessary to lower the moisture to below 10%. Here, SXHG-2424 rotary dryer and SXLQ-2424 rotary cooler are excellent choices for the excessive water removing in 150,000 t/y compound fertilizer production project.

Automatic Packaging Scale

Automatic bagging equipment can help you package finished compound fertilizer powder or pellets into 10 kg/bag, 25 kg/bag, 50 kg/bag, etc. So you can sell fertilizer to your customers in a targeted way. For capacity of 150,000 tons per year, SX especially design double buckets packaging scale and ton bag packing machine for your choice.

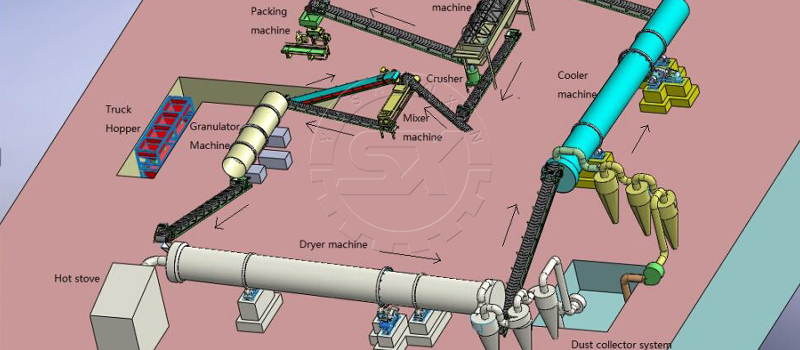

The rotary drum granulation machine is suitable for large-capacity compound fertilizer production lines. Furthermore, fertilizer manufacturers usually favore it.

Its granulation process belongs to wet granulation, and you need to subsequent dryers and coolers . In order to prevent dust pollution, a dust collector is also essential.Of course, the ingredients in the early stage are also very important.

From the above point of view, the cost is indeed much higher. But for fertilizer manufacturers, they cannot ignore the role of the rotary drum granulator in the compound fertilizer production line.

It can produce a large amount of granular fertilizer with high efficiency. In the production line, it is like Dinghaishenzhen, but the premise is that the ingredients are rigorous and qualified. So are you sure you don’t want to try this equipment?

What is the Moisture Requirement of Making Compound Fertilizer with Granulation Process?

There are two granulation process for you to make compound fertilizer. Wet granulation method and dry granulation method. No matter which pelleting method you choose, they all have different moisture requirements.

If you choose wet granulation process to make compound fertilizer, as its name says, the water requirements are very strict in the process of producing compound fertilizers. Before granulation, you need to control the moisture below 30%. For this, you can use SX dewatering machine. It can help you separate solid with liquid fast and effectively. Then, in the process of producing compound fertilizer, you must add water to increase the moisture content of the material to 45%-50% . Because this granulation method uses water as a binder to agglomerate the material into balls. Hence, water plays an important role in producing compound fertilizer. Finally, after pelleting, in order to facilitate the transportation and storage of the final compound fertilizer, packaging is essential. How much moisture can meet the packaging standard? Below 25%. So, you can use dryer and cooler to accomplish moisture requirements.

Dry granulation greatly reduces the requirement for moisture. It adopts extrusion granulation, which makes the final granules harder. Therefore, dry granulation requires the moisture content of the material to be below 10%. After granulation, you cannot dry and cool the final fertilizer which reduce the related costs.

How to make organic compound fertilizer production line?

According to its literal meaning, the organic compound fertilizer production line is a production line in which mixing organic fertilizers and compound fertilizers .

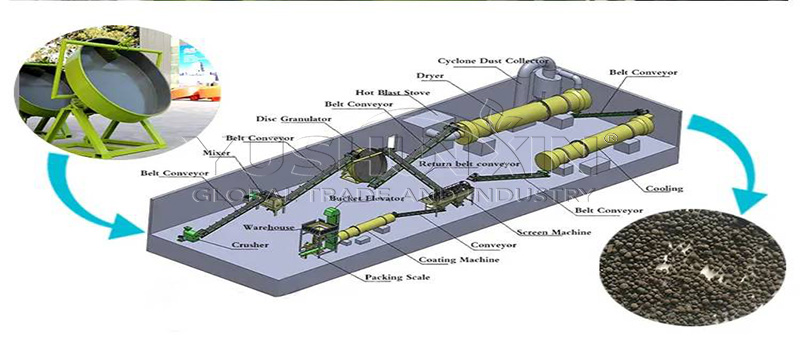

Organic fertilizers can turn waste into treasure and purify the environment. Compound fertilizers contain many trace elements, which can provide good nutrients for soil and crops. The formula of organic compound fertilizer can produce fertilizers with different effects according to the adjustment of organic matter and the ratio of nitrogen, phosphorus and potassium. In order to produce this kind of fertilizer, you need firstly to crush these raw materials. Then mixing the raw materials required in the compound fertilizer. After that putting the organic raw materials and compound raw materials together for stirring. After stirring, the disc granulator can be used for granulation. Because this kind of granulation belongs to wet granulation, so it needs to be dried and cooled.

How to Adjust the Pellet Size during Compound Fertilizer Granulation?

Generally, our compound fertilizer granulators can fully meet your requirements of making 1-10 mm compound pellets. However, different pellet equipment has different granule size regulation methods.

Disc Compound Fertilizer Pelletizer

Drum Compound Fertilizer Pellet Making Machine

Double Roller Compound Fertilizer Granulator

How to Reduce your Compound Fertilizer Plant Cost?

In sum up, if you want to setup a compound fertilizer plant at a lower cost, you can act from the following aspects: