In order to prepare higher quality fertilizer and make more profits from fertilizer production, more and more fertilizer manufacturers prefer to invest in granular fertilizer making. Then to meet the requirements for fertilizer granulation, we design various pellets making machines for your choice. Pan pelletizer is one of them and has won the trust of fertilizer suppliers at home and abroad. So when you set up a disc granulator fertilizer production line, it can better produce fertilizer granules. And whether you want to process chicken manure, cow dung or NPK into fertilizer pellets, this plant can complete it quickly. In addition, disc granulation plant only needs low investment and a small area site. So if you want to start your fertilizer manufacturing business, it will be an ideal choice for you!

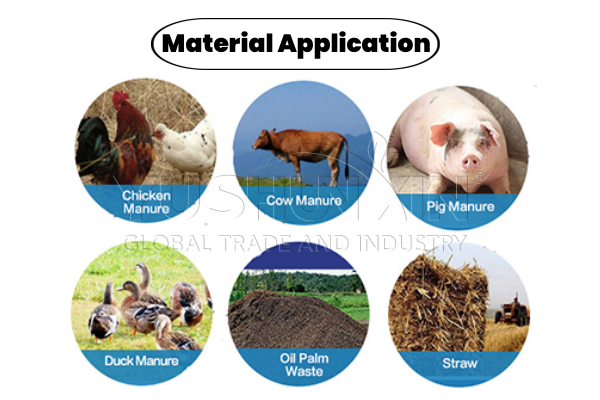

What raw materials are suitable for disc granulation plant?

When choosing a suitable fertilizer production line for your fertilizer plant, it is important to consider if the line can process the materials you have. Whether you aim to produce organic fertilizer, compound fertilizer, or bio fertilizer, the SX disc pelleting line is an excellent option for you. In the pan granulation line, there are various materials that you can use. Some of these materials include:

Material for organic fertilizer or bio fertilizer making

Material for compound fertilizer production

What granulation method is used in pan granulation line?

The wet granulation method is primarily employed in the fertilizer pan granulation line. This technique involves utilizing liquid as a binder to enhance the adhesive force between fertilizer powders. Consequently, the resulting fertilizer pellets possess a higher density and exhibit resistance against pulverization. Such fertilizers can be easily transported and stored. To facilitate the addition of liquid during the operation of the disc granulation line, we have incorporated a specially designed spraying device above the pan pelleting machine. As the powdery material is conveyed into the disc pelletizer and the disc commences its rotation, you have full control over the quantity of liquid sprayed by this apparatus. And this capability greatly contributes to the improvement of fertilizer particle quality.

Top 2 popular disc granulation lines for your choice

From the above, we can know that the pan granulation production line can be used in organic and compound fertilizer making. Is there any difference between them? There are some details about them for your reference.

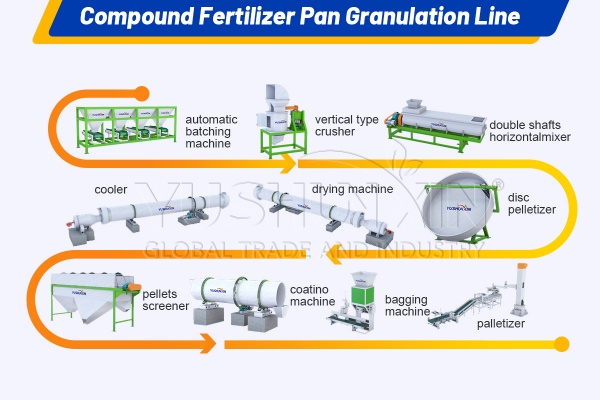

Compound fertilizer disc granulation plant

Organic fertilizer pan pelleting line

- 1

Capacity: 0.02-6 t/h

- 2

Final shape: Granules

- 3

Final granule size: 3-10 mm

- 4

Equipment types: Dewatering machine, composter, crusher, mixer, disc granulator, dryer&cooler, screener, packaging equipment, etc

- 5

Application materials: Animal manure, straw, rice husk, sawdust, mushroom waste, biogas residue

How to change the size of fertilizer pellets in disc granulator fertilizer plant?

During granular fertilizer making, there is an item many fertilizer manufacturers focus on. It is how to produce fertilizer pellet of the required size? 0r how to change fertilizer granule size? If you choose to make organic or compound fertilizer by pan granulation line, our engineers have two advice for you.

Control moisture content

Water content plays an important role in fertilizer pellet size regulation. Generally speaking, less water, smaller size; much water, bigger size. And in order to make it easier to control the moisture content of fertilizer material, we especially design spraying device above the pan granulating machine.

Adjust the disc angle of granulator

For fertilizer pan granulation line, there is also another method to change your fertilizer particle size. You can finish it by adjusting the disc angle between 35 degrees and 55 degrees. Sharp slope, smaller size; slow slope, bigger size. Doing this, you can produce fertilizer granule with a diameter you need within 1-8 mm.

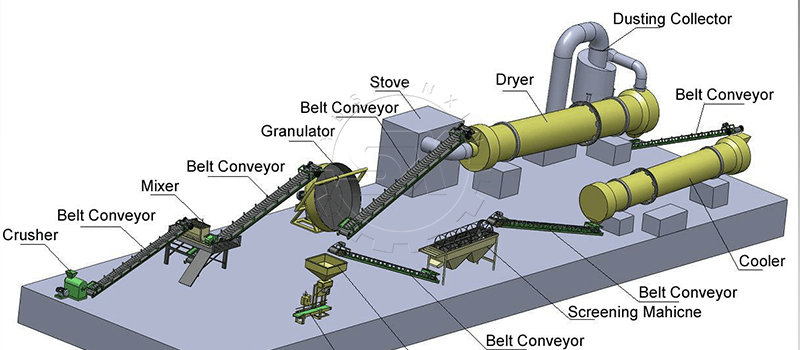

How to make granules fertilizer in pan production line?

The disc granulation production line is low in cost, easy to operate, and has a high pelleting rate. Below I will introduce its production process for you.

Why should you have a disc granulator fertilizer production line?

There are many benefits to owning a disc granulation production line, let’s start with its performance.

Selection equipment for disc granulator fertilizer plant

According to the different production environment and production requirements, you can choose the material and shape of the disc granulator by themselves. According to different production requirements, the diameter of the selected disc is also different from 1800-3600mm. Then you can choose according to the parameters. If the output is large, they can also purchase multiple sets to improve production efficiency.

Moisture for making fertilizer in the pan granulator fertilizer production line

The moisture of the material is very important in the whole production line. It is related to the fertilizer efficiency and hardness of the fertilizer. In addition, the composition and moisture of raw materials determine the pelleting rate of fertilizer granules in the disc granulator. To ensure good moisture uniformity and material composition that can be rolled into balls, the moisture required for pelleting cannot be reduced due to later drying. Because it will cause seriously affect the ball into the rate.

4 Ways to increase capacity of pan granulator fertilizer production line

For a fertilizer manufacturer, the output of a disc pelleting line is of the most importance. But how to get a high capacity of your line? We should pay special attention to the key equipment in the fertilizer production plant – disc granulator.

Through the improvement and understanding of the disc granulator, the efficiency of the entire production line can be improved overall.