We have a special plan for the capacity of 40 mt per hour NPK granulation production line. There are two options: one is 14:14:14 fertilizer blending production line,the other one is 46:0:0 granular fertilizer making plant. You can choose the plan that suits you according to your needs.

2 Kinds of Proportion 40MT/H NPK Fertilizer in the Production Line for Your Choice

Two different ratios of NPK fertilizers can be produced in various forms, such as bulk blending fertilizer or granular fertilizer. Below our professional fertilizer equipment production engineers will introduce the process of producing these two ratio fertilizers respectively.

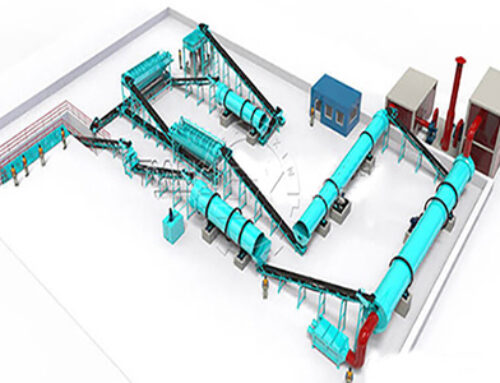

How to Prepare 40MT/H 14:14:14 Fertilizer in Your Blending Production Plant?

Tips:

The NPK fertilizer produced through the above steps and equipment can promote root growth and protects it from drying (adjusts the amount of water vapor, helps in CO2 and oxygen circulation).

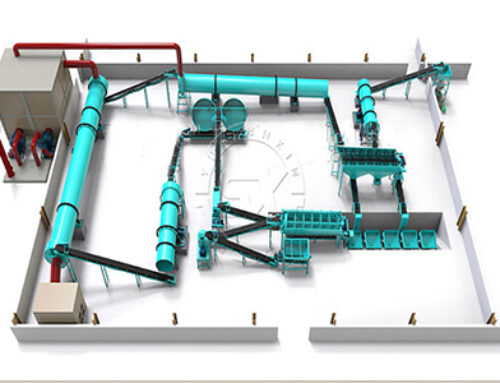

How to Make 40MT/H Powder Fertilizer into 46:0:0 Granular Fertilizer?

40MTPH NPK Fertilizer Granulation Machine

How to choose a suitable granulator after batching? What kind can you use? Here we recommend the combination of drum granulator and disc granulation. Because your capacity is 40MTPH, the maximum output of the drum granulator can reach 15-30t/h. The maximum capacity of the disc granulator can reach 4-6 t/h. So the two-in-one production line is very suitable for you to produce NPK granular fertilizer with 40MTPH capacity.

Drying&Cooling the 46:0:0 Granular Fertilizer

Since the above-mentioned granulation is drum-disc two-in-one granulation, it belongs to wet granulation. The water content will be increased to 45%-50% before granulation. The bagging of granular fertilizer requires a moisture content of less than 25%. So only after drying and cooling, you can pack.

Package Process for Produce NPK Fertilizer

After drying&cooling, providing you a automatic bagging machine is necessary. Because of your 40MTPH NPK fertilizer, you pack them by manpower that make you spend more labor cost and decrease the efficiency. So this machine is suitable for you.