Chicken manure looks ordinary in daily life, but in fact it has great uses. It can turn waste into treasure for fertilizer manufacturers. Putting chicken manure into fertilizer production not only reduces the environmental pressure to a limited extent, but also improves the utilization rate of chicken manure. We can provide you with the whole chicken manure fertilizer production line and customize it according to your needs. The quality of the equipment is guaranteed. Please see my detailed introduction below.

Technology for the manufacture of fertilizer from chicken manure

Chicken manure fertilizer is not as simple as going through the process on the making fertilizer production, and the process is the most important. It is related to the effect of the final fertilizer product.

The process used in the composting part is aerobic fermentation. Our company’s organic fertilizer fermentation tank is just in line with this process. Harmless fermentation, airtight production, no dust hazard.

The granulators suitable for wet granulation in the chicken manure production line include disc granulation machine and churning granulators. The disc granulator has a small granulation output but low cost. The tooth-stirring granulator has a high requirement for the moisture content of the material, which should be at 50% moisture. In addition, you can add another rounding machine due to uneven particles.

The granulation suitable for dry granulation in the chicken manure production line includes a double-roll granulation and a flat die granulator. Furthermore, the particle size produced by the double-roll granulator is 3-6mm, and the particles are uniform and low in moisture. The flat die granulator does not need to dry and pulverize the raw materials before granulating. And it can process cylindrical granules directly by batching. In addition, you can configure a variety of molds to produce columnar particles with a diameter of 2-8mm to meet different needs.

Judging from the above, our company’s equipment is very mature, so you are welcome to buy it.

Different scales of production line with different equipment

Small-scale Chicken Manure Production Line

Generally, the output of small-scale production lines is 1-3 tons, so you can equip with the equipment accordingly. In the composting stage, you can use the groove type compost machine. It has low cost and high turning efficiency. The granulation equipment can choose our company’s disc granulator, the output is small and the cost is low. And the granulation rate can reach more than 93%. In addition, you can arrange other auxiliary equipment according to your needs.

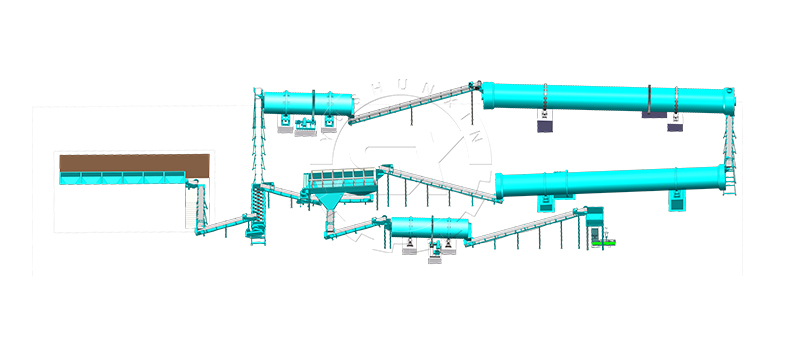

Large-scale Chicken Manure Production Line

The output of large-scale production line is 18-20 tons. Therefore, if your composting site is large and the funds are sufficient, it is recommended that you buy our company’s wheel-type turning machine. Because it has a large output and automatic feeding and discharging. The granulation equipment can choose a rotary drum granulation machine, which has a large output and the rubber lining is not easy to corrode. This kind of wet granulation needs to buy a dryer.

Based on the above two production lines, choose the chicken manure production line that suits you, and we are waiting for your reply.

Chicken manure for disposal and recycling in your plant

Chicken manure may be just animal manure to us, but if you use it effectively, it can exert huge energy. In your production line, it is like the protagonist.

This set of processes is a complete chicken manure production line, which maximizes the use of chicken manure. You can realize the win-win situation of cost and environment.

How to save electricity cost in your chicken manure production line?

A large amount of gas is produced during the fermentation and decomposing stage of chicken manure, which can be converted into the required electricity after conversion. In this case, it not only saves energy and protects the environment, but also can effectively reduce costs. If your site is large and equipped with a lot of equipment, this method can save money to the greatest extent and ensure follow-up operations.