The agriculture development plays an important role in Lebanon. But how to improve the quality of crops to make more profits? Putting some organic fertilizer in your crops is the excellent choice for you. Because organic fertilizer have more organic matter, which contains nutrients needed by crops. However, how to make high quality organic fertilizer? You can convert animal waste into them. In this process, composting is necessary. But in natural conditions, manure composting will take a long time. So on 4th March 2023, a customer from Lebanon inquired about 3 tons per hour composting system. The following are the specific details of our communication in this case.

How Do you Test the Success of Cow Dung and Chicken Manure Composting?

The main requirement of this Lebanese customer is making cow dung and chicken manure into compost in a short time. So it is very important to learn to judge whether the cow dung and chicken manure composting is successful. In this way, you will not waste time during the composting process and improve the composting efficiency. Hence, temperature and odor are the keys for your attention.

What Equipment is Suitable for 3T/H Composting System with Less Affected by Seasons?

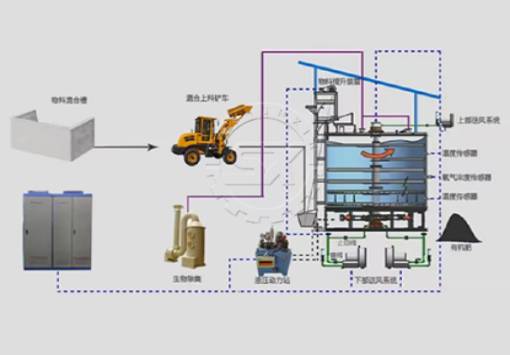

From the above introduction, we know that temperature and odor are the keys in the success of cow dung and chicken manure composting. But what equipment can help you start 3 tons per hours composting all over the year? You need to consider your conditions. For example, customer from Lebanon wanted produce 3 tons per hour composting manure all over the year. We recommended him to choose the in-vessel composter. The reason is as follows:

How to Further Make Compost into 3 T/H Organic Fertilizer?

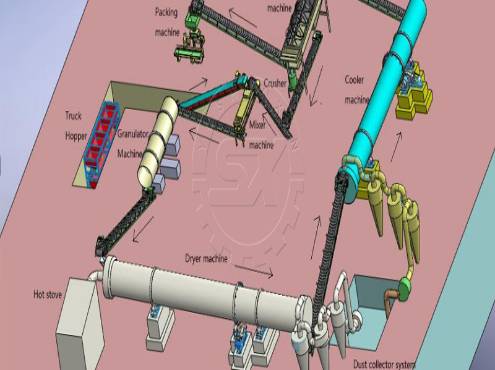

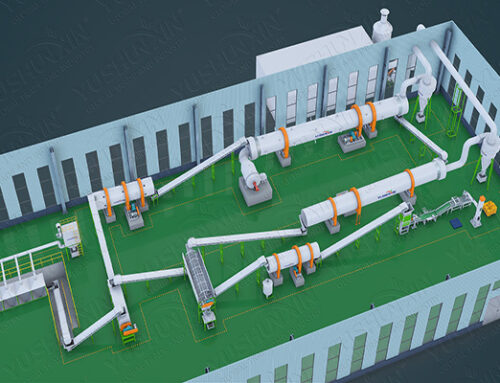

Finally, after composting, how to make more profits from the composting manure? You can further process compost into organic fertilizer. For example, the Lebanese customer wanted to have a 3 tons per hour composting line system. In general, you can choose to make compost into two forms of organic fertilizer. Powder organic fertilizer or organic fertilizer granule. For this, we can provide professional organic fertilizer manufacturing plans.

They can help you turn compost into quality granular organic fertilizer, which has a higher competitiveness in the market. Because granule fertilizer is more convenient to transport, store and use. Therefore, this fertilizer manufacturing system can help you make profits in a shorter time, even less than one year.