What Kind of Material Can Manure Separator Manufacturing?

For organic fertilizer making, there are various materials for your choice. For animal manure, you can use chicken manure, cow dung, etc. Can manure dewatering machine process all of them? Of course. We can provide you with the most suitable manure separator according to your material.

How does a Manure Separator Work to Remove Excessive Moisture?

In order to better achieve the dehydration effect, you need to know how does the separator to remove excessive moisture. Then you can carry out the follow-up operation and use it in your production line effectively.

Which Type of Manure Separator Equipment Do you Want to Choose in our Factory?

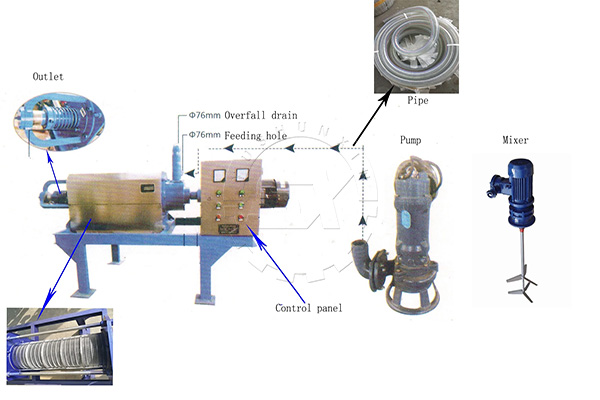

In our factory, there are two types of manure separators for your choices. The one is screw press dewatering machine, the other one is inclined screen separator. The two machines have different dewatering process and models.

Screw Press Dewatering Machine for Sale

| Model |

Capacity(m³/h) |

Powder(kw) |

Dimensions(mm) |

|---|---|---|---|

| SXTS-180 |

10-15 |

4 |

1850*650*1150 |

|

SXTS-230 |

15-20 |

4 |

1850*800*1150 |

Inclined Screen Separator for Sale

| Model |

Capacity(m³/h) |

Powder(kw) |

Dimensions(mm) |

|---|---|---|---|

| SXTS-800 |

15-20 |

4 |

1700*1500*1300 |

|

SXTS-1200 |

30-40 |

5.5 |

2200*1500*1700 |

Based on the above data, you can choose the equipment suitable for your site according to your own needs. Furthermore, the corresponding price will vary. In addition, our company has equipment patent certificate, professional degree is guaranteed.

How to get drying fertilizer after manure separation?

Generally, the moisture content of manure is more than 50%, and about 30% after dewatering. However, if the moisture content of manure is too high, you will be difficult to granulate.

What’s more, it is inconvenient to pack and storage in the end. Therefore, you can consider drying fertilizer. Because it can help remove excessive moisture from manure and get the suitable state to make organic fertilizer. But in the process of drying fertilizer, it can produce some exhausted gas. For this, we design the dust collector to protect your production environment.

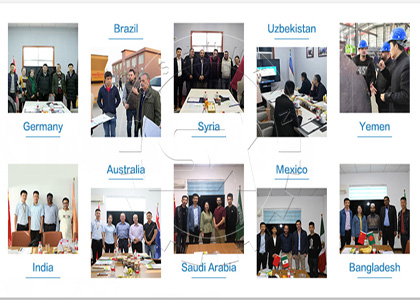

Top manure separator manufacturer

SX is one of the top manure separator suppliers. We have helped hundreds of clients with their animal waste management projects. So what service can we offer for you?

Value-added Products

The separated solid and liquid fractions can be used as valuable resources for composting, fertilizer production, biogas production, or bedding material.

What is the benefit of manure separation?

After manure separation, you can use disposed manure for organic fertilizer production. We can offer some suitable compost turners and some organic fertilizer making machines for you. Welcome to contact us!