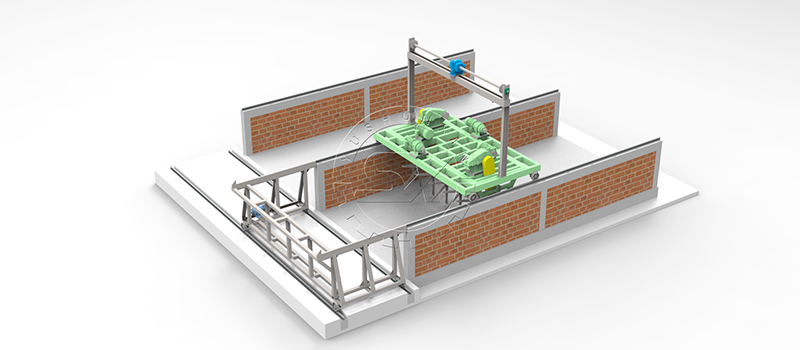

The composting machine is a kind of turning equipment used in conjunction with the organic fertilizer fermentation tank.So it is also called a groove type composting machine. In addition, you can use it to ferment organic raw materials in the production process of organic fertilizer, compound fertilizer and other fertilizers.Therefore, groove type composting powder fertilizer system is a fertilizer production line with a groove type composting machine as the main equipment.

The composting machine is a very important equipment in the production line. As a kind of fertilizer production line, powdered fertilizer production line is also very popular among fertilizer manufacturers. But compared with the granular fertilizer production line, this kind of production line is more affordable in the fertilizer production process. Therefore, it is also very applicable to combine the trough turning machine with the powdered fertilizer production line. It is called groove type composting powder fertilizer system. Below I will introduce them in detail.

Groove type composting system for powder fertilizer production

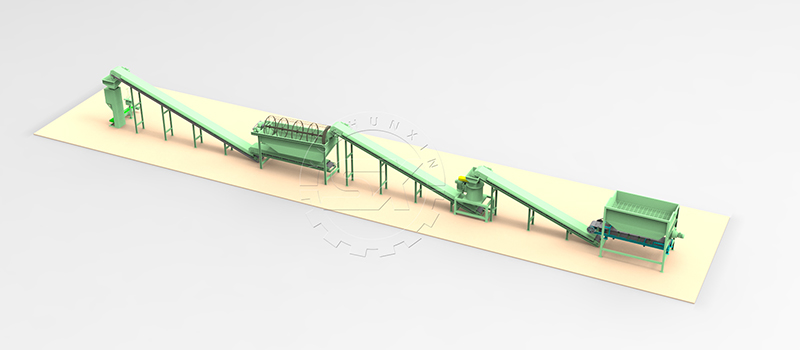

The production process of the powdered fertilizer production line looks simple, but in fact there are still many things worth noting in the details.

The above is the production process of the powdered fertilizer production line. If you want to know more, welcome to consult.

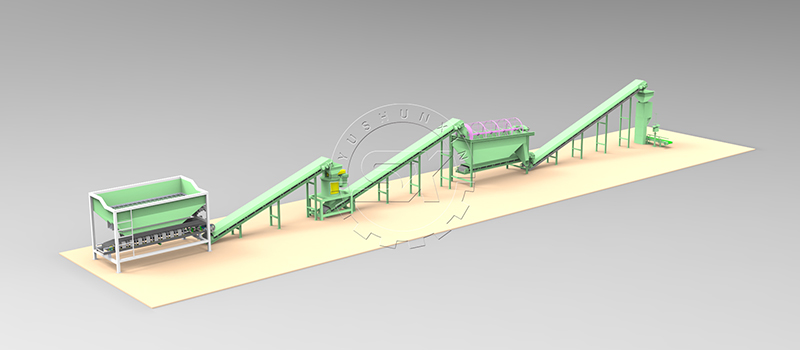

What are the benefits of using our groove type composting machine in your powder fertilizer production line?

In the powder fertilizer production line, composting is a very important process. Because it determines the final fertilizer efficiency of the fertilizer. Therefore, in order to finally produce high-quality fertilizers, you need to specially pay attention to the composting process in the early stage. And it is necessary to choose a high-quality turner. Our trough turning machine is worth choosing, and has the following advantages.

6 application of groove type composting machine for powder fertilizer production

The groove type turning machine has a wide range of uses. And it can effectively expand the capacity of the powdered fertilizer production line. In addition, with its own characteristics, it can improve the overall effect of the production line.

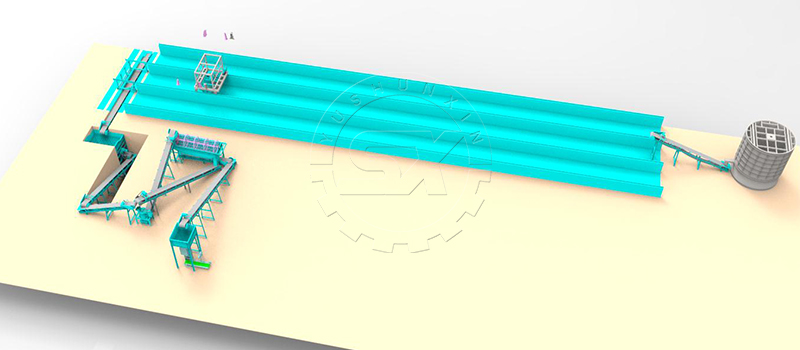

Tips:When you turne over through the equipment, it will automatically lift up and down hydraulically. And then you can adjust to the quick return position to start the work of the next slot.

What is the role of the groove type turning machine in the powder fertilizer production line?

After that you can ferment the raw material, whichit heats up. So that the fermented material is fully in contact with the air. And increasing the oxygen content of the material pile . It also volatilizes the water vapor in the material pile and reduces the temperature of the material pile.

Using a trough-type turning machine for fermentation can improve the fermentation process of organic fertilizers. It can increase the traditional fermentation period of several months to 7-15 days.

The groove type composting machine also performs oxygenation, crushing and stirring operations on the materials while transporting the materials. The characteristic of the overall feeding and discharging is that you need fully feed the entire fermenter at one time. When the fermentation cycle is over, you can discharge the material at one time.

Using bacteria with groove type composting machine to make your powder fertilizer production better

In order to improve the fertilizer efficiency of the fertilizer, you can add bacteria agents during the turning and throwing process. So that the fertilizer will finally reach a perfect state. So as to meet your requirements of moisture and pH during the fermentation of raw fertilizer, you need to add some auxiliary agents.

Composting process can bring you benefits for making powder fertilizer

After the groove-type turning machine turns over, forming a new plurality of stacks . And the new pile is in a fluffy and loose state, creating a favorable aerobic state for material fermentation. It is very conducive to the production and fermentation of organic fertilizers.