In general, to supply nutrients to the growth of crops in a balanced way, fertilizer manufacturers will produce organic fertilizer from manure. At the same time, bentonite powder is prepared to provide nutrients to plants in a targeted way. But can we make poultry manure into organic fertilizer with richer bentonite powder? On 25th July 2023, a micro silica exporters and supplier from India inquired about organic and inorganic compound fertilizer production. He told us “ our raw material is Rice Husk Ash and poultry manure in which we add around 3-4% of bentonite powder and 10-12% moisture to attain granules , which is making organic and inorganic compound granulated fertilizer.” The following are the specific details in this case:

Can We Add Rice Husk Ash to Bentonite Powder to Start Organic and Inorganic Compound Fertilizer Production?

The customer from India wanted to manufacture inorganic bentonite enriched compost fertilizer from poultry manure and Rice Husk Ash out of local farming requirements. The prior thing you must know is whether you can add bentonite to poultry manure and Rice Husk Ash? Of course. It is greatly helpful for improving the quality of poultry poop compost making. Then is spreading bentonite directly to poultry manure enough? No. In order to produce quality organic and inorganic compound fertilizer, it is advisable to process bentonite in the following steps:

Crushing Bentonite into Fine Powder

Whether you plan to process poultry compost into powder fertilizer or granular fertilizer, it is necessary to crush bentonite into fine powder. For one thing, after crushing, bentonite is not easy to stick to each other. So after being processed into powder poultry manure fertilizer and Rice Husk Ash, it is more convenient to transport, store and use. And the uniform particle size is beneficial for preventing nutrient layering and improving the purchasing willing of your customers. For another, bentonite crushing is also essential for organic and inorganic compound fertilizer granule production. Because the finer the bentonite powder, the better the granulation effect.

Is there a crushing machine suitable for bentonite powder making?

Mixing Bentonite Powder with Animal Manure and Rice Husk Ash Evenly

Then in order to prepare organic and inorganic compound fertilizer with balanced nutrient, you also need to mix bentonite powder with poultry manure compost and Rice Husk Ash evenly. Of course, at that time, poultry manure compost is also fine powder. And there are various types of mixers for your choice. When you want to process a large amount of bentonite powder and poultry poop compost, we recommend you choose horizontal mixer. Its largest output can reach 15 t/h. In addition, for those who want to mix them evenly quickly, we design double shafts horizontal blender for you. However, if you want to finish small scale fertilizer blending at a low cost, like the client from India, you can choose disc mixer.

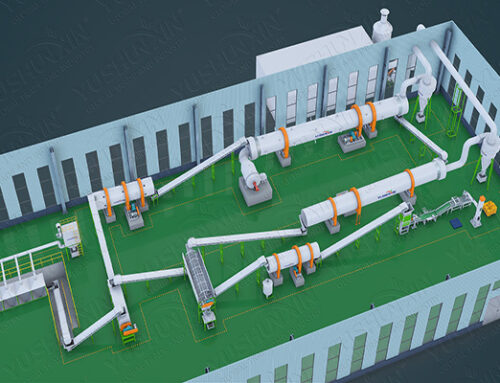

How to Make Organic and Inorganic Compound Fertilizer Pellets in India?

In order to make more profits, this India customer told us that he plans to make poultry manure&Rice Husk Ash + bentonite compost into granular organic and inorganic compound fertilizer. And he asked us how to finish it? For this, we can provide you with professional machines for compost fertilizer granulation.