In our daily life, a large amount of organic waste is produced every day. Including animal manure, straw, maize stocks, sugarcane residues, wine waste etc. If you leave them alone, they will have a serious impact on the surrounding environment. So it is necessary to find the right way to manage these organic wastes. But no matter how you want to make use of it, you must complete the harmless process of organic litter. Especially making organic litter into organic fertilizer. For this, making manure into compost is an ideal choice. Because during composting, all harmful bacteria, pest eggs and grass seeds will be killed thoroughly. In this way, you can use organic litter as fertilizer without any harm. With the rapid development of organic agriculture today, please believe that your choice of compost fertilizer making project is worthwhile. And SX can provide you with various compost production machines. You can choose the most suitable one according to your needs.

What is the process of making compost fertilizer?

In general, a complete compost fertilizer production process can be divided into three parts. Pre-composting preparation, composting period and further processing. During pre-compost preparation, you need to focus on the moisture control and material size. Doing them well can create conditions for better aerobic fermentation and shorten the entire production cycle. During composting, professional composting machines will work to help you kill the harmful bacteria, pest eggs and grass seeds in organic material. So it is no longer harmful for crop growth, if using it directly as fertilizer. Then if you compost organic waste for commercial purposes and want to improve your compost competitiveness, you can further process it into organic fertilizer pellets.

What can you do for better compost fertilizer making in pre-composting preparation?

In this pre-composting preparation, there are two things you can do to create a better environment for organic fertilizer fermentation.

Create a suitable humidity condition for better composting

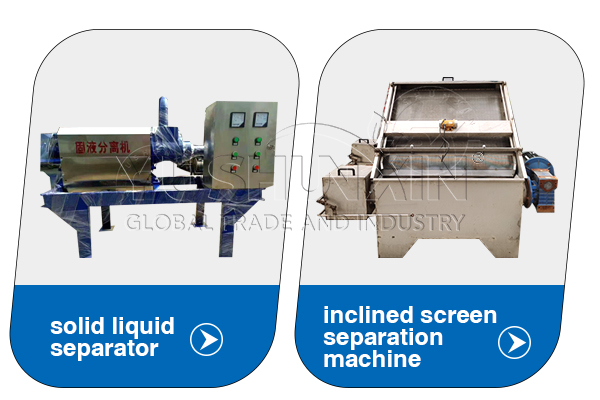

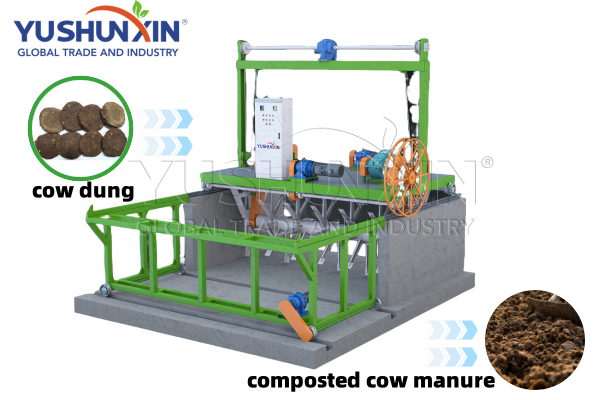

Generally speaking, the most suitable material moisture content for composting fertilizer making is 45%- 65%. However, the main materials of compost fertilizer production usually have a high water content. Which can reach 70%-80%, and even 90%. Such as cow dung, chicken manure, sludge, etc. Here, SX can offer you professional dewatering machine, which can help you remove excessive water from manure quickly and easily. Using this machine, you can reduce the moisture content of compost to 30%-40%. Then, after a preliminary processing process, you can use fertilizer compost making machine to start aerobic fermentation.

Enlarge the contact area of compost pile with oxygen

In compost fertilizer manufacturing, sufficient oxygen supply is an item you must focus on. Because this is the reason why microorganisms in organic waste have enough energy to decompose organic matter and generate enough heat to kill the harmful substances in compost piles. For this, it is an excellent choice to enlarge the contact area of compost with oxygen. Here, crushing machine can help you a lot. It can grind big caking and agglomerate into fine powder. In this way, the compost materials can fully contact with oxygen and make better fermentation.

Which composting machine is suitable for your organic fertilizer plant?

For aerobic fermentation process, the key equipment is the compost fertilizer making machine. As a professional fertilizer equipment supplier, SX has different kinds of compost machines for your to choose: trench compost turning facility, windrow composting equipment and in-vessel fermentation tank, etc. Using a compost facilities in the fertilizer making process is a mechanic way to accelerating the fermentation process, it will turn over materials to increase oxygen supply and the porosity of the compost piles.

How to run a compost fertilizer business with low cost?

If your budget is limited, you can start with a small compost fertilizer business with low cost. For small scale compost fertilizer business, SX has designed a powder compost fertilizer production line for you. In this production line, the main compost fertilizer making machine includes the compost turner, SX new type vertical compost fertilizer crusher, rotary screen machine, belt conveyor and the compost fertilizer packaging equipment. This production line runs smoothly and has strong adaptability to the working field. If you have any special requirements for the facilities in this production line, welcome to contact us freely, We can communicate about the details of this project and provide customized service for you.

5 tips to plant design for compost production

To have a complete composting manure production line, the equipment must be complete.

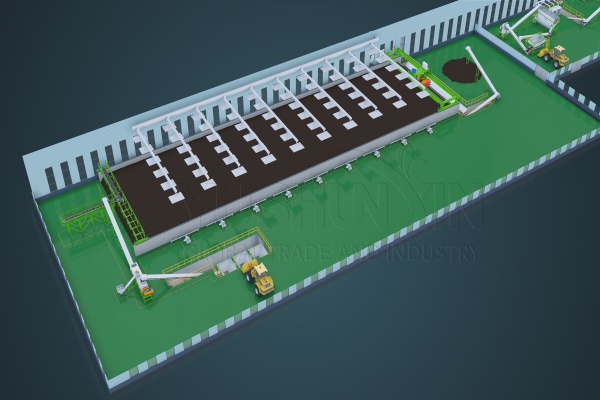

In addition, the choice of composting site is also required.The composting yard includes a raw material temporary storage area, a composting operation area and a product packaging storage area, ect.As far as the composting operation area need to concern, the amount and speed of raw material feeding, component content and moisture content all directly affect the size of the site demand.Therefore,you need to consider the choice of venue from many aspects.