For chicken farm manure management, turning it into compost fertilizer is an ideal choice. But according to the different actual conditions of chicken farms, there are different chicken poop composting lines needed. Then how to compost chicken poop from 120,000 chicks farm? On 15th August 2023, a customer from Pakistan inquired about this. He wanted to know the layer manure fermentation process and get suitable fertilizer equipment recommendations.

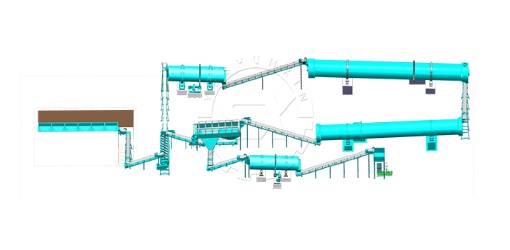

What Equipment is Needed for Composting 120,000 Chicks?

Which Fermentation Method is Suitable for 120,000 Chicks Manure Disposal?

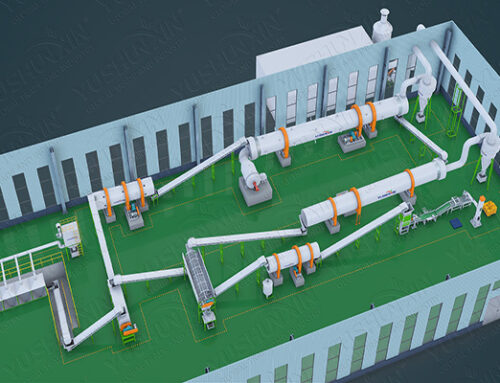

Finally, this customer from Pakistan wanted to know what fermentation method can speed up chicken manure composting. In general, SX fertilizer equipment mainly adopts aerobic fermentation method. While working, it will turn chicken waste piles to supply oxygen for better fermentation and dissipate excessive heat for preventing beneficial bacteria death. But why should you choose this fermentation method to dispose of chicken waste? Because it makes use of high temperature, which is caused by microorganisms activities, to complete the harmless process of chicken manure. For this, SX can recommend you the BLXQ-6000 in-vessel composter to compost 120,000 chicks scale of manure.

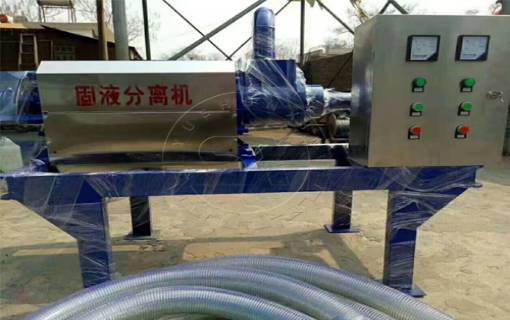

Generally, it can help you can help you process 8-12 m³of chicken manure per day, which has a moisture content of 50%-70%. And after chicken manure composting, you can get 4-5 m³of compost fertilizer a day, which the moisture of composted chicken manure is 30%. According to 120,000 chicks scale, you can buy two organic fertilizer fermentation tanks in your factory. Can it compost chicken manure with moisture content of over 70%? At that time, you can use manure dewatering machine to excessive waster from chicken poop.