Which Equipment is suitable for Making Compound NPK Fertilizer?

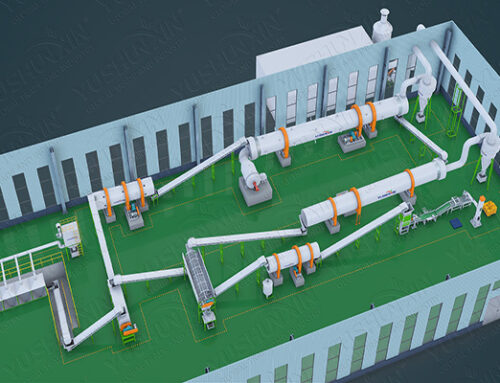

Customer wanted to use DAP, MOP, Urea and SOA to prepare compound NPK fertilizer pellets. So first of all, it is essential to buy a type of suitable chemical fertilizer granulation machines.

How to Increase the Strength of Compound NPK Pellets?

If Compound NPK fertilizer wants to increase its particle hardness, it needs to finely crush the material in the early stage. Because the finer the powder and the denser the granules, the harder the fertilizer will be. If you choose wet granulation, you can add some binder during the mixing process to increase the hardness of the granules. Or you can increase the temperature in the drying process and reduce the moisture in the fertilizer to increase the hardness. In addition, the temperature control of the dryer is also very important. Temperature control within a certain range can also effectively enhance particle hardness.

How Much Does Compound NPK Fertilizer Granulator Cost?

In addition, in the process of choosing compound NPK ferilizer granulator, cost is also an item you must focus on. In general, when you plan to buy disc compound NPK fertilizer granulator for your fertilizer production line, you need to prepare about $1,000-$16,000 for it. How about drum compound NPK granulation equipment? The price of a rotary drum pellet making machine is $7,200 and $69,000.