How to make fertilizer in your wheel type compost system?

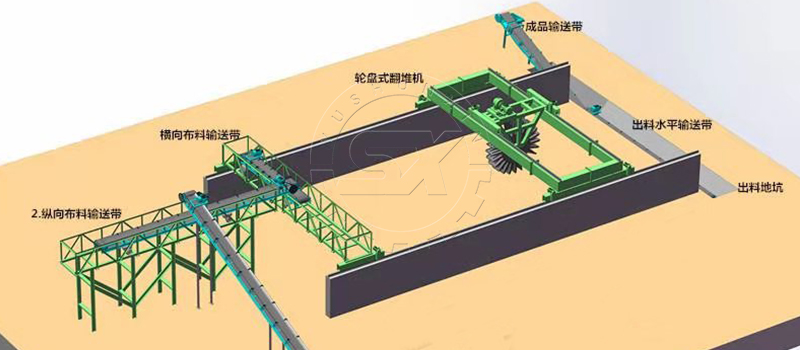

If the water content of the material is too high in the early stage, you can use a dehydrator. After that you can use a roulette turner for turning and throwing. Then you can crush through a semi-wet material pulverizer , and mix through a horizontal mixer. Next, you can granulate and dry & cool. You can use a drum screening machine to sieve the finished granules. And the granules are optimized as a whole by a coating machine. Finally pack it. Using the belt conveyor to transport the whole process.

The production process of the following two configurations is similar to the above and will not be introduced in detail. You can buy semi-wet material crusher, horizontal mixer, granulator, dryer, cooler, drum screening machine, packaging equipment, belt conveyor, etc.

You can buy semi-wet material crusher, horizontal mixer, granulator/drum screening machine, packaging equipment, belt conveyor, etc.

The fermentation process for the wheel type compost system

If you want the roulette turner to play the most effective role in the production line, you need to know its fermentation process for subsequent operation rectification.

Wide application for wheel type compost system

How to make the wheel type turning production line more automated?

The roulette turning and throwing machine plays a very important role in the fermentation process of the production line, but in order to exert its maximum effectiveness, some auxiliary equipment is also essential. For example: fabric vehicles, mobile vehicles, aeration systems, etc. There are also palletizing robots in the final packaging process. These auxiliary equipment make the whole production line more automatic. Next, I will introduce the role of these devices in the production line.

It can be seen from the above introduction that each device plays an important role in the entire production line, which makes the degree of automation higher.

How to avoid the agglomeration and precipitation of raw materials during the operation of the wheel-type turning production line ?

There are often some problems in the turning and throwing process of the roulette turning machine, such as agglomeration and sedimentation. If agglomeration often occurs, it is mostly related to the temperature, humidity, external pressure and storage time of the material. These problems will lead to a decline in the overall operating efficiency of the production line, so how to avoid it?

When choosing raw materials, you can try to choose those that are not easy to agglomerate, such as trace element foliar fertilizers, iron, copper, manganese, zinc, sulfate, etc. as raw materials, and magnesium sulfate as the main additive. Helps keep materials within a suitable environmental range.

Because in spring, late autumn, and winter, the air humidity is low and the temperature is high, which will not create strong conditions for agglomeration. So the operator can choose to process during these times. You can add some anti-caking agents appropriately, such as talcum powder, humic acid, etc.

In addition, during the transportation of the roulette turning machine, you need to pay attention to prevent extrusion and ensure moisture absorption and air permeability. After finishing the installation of the roulette turning machine and before use, personnel should try not to run the production line on an empty stomach during the trial run. The engine must be heated and fed to avoid sticking, so that abnormalities can be detected as early as possible. At the same time, for its feed port, prohibiting iron and other sundries strictly in the vent hole.