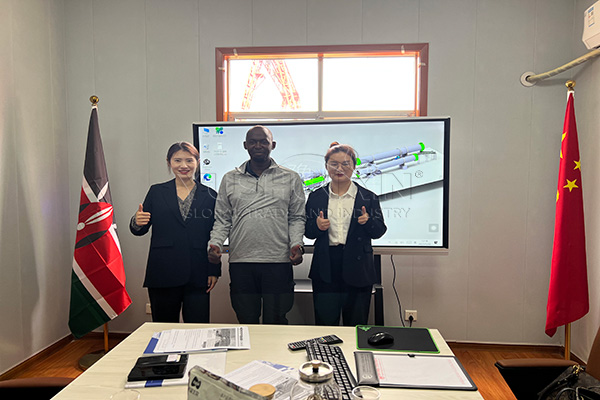

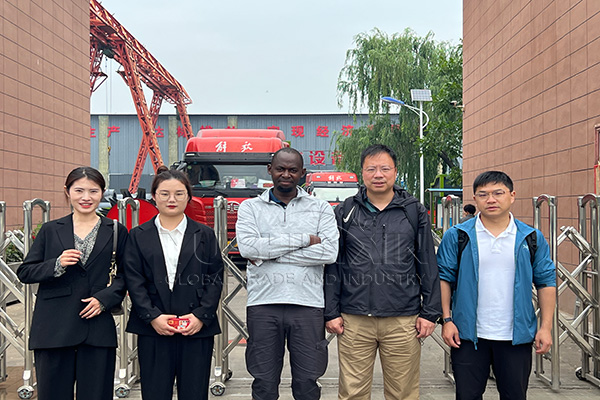

On November 21, 2023, we receive an inquiry about disc granulation plant at Kenya. This customer mainly engages in agricultural industries and wants to improve their fertilizer production capabilities. After discussing and customizing the corresponding solution, the client’s UK boss finally reached this deal. So the following is the specific information about the entire process.

What is the requirement of Kenyans customer about making organic fertilizer?

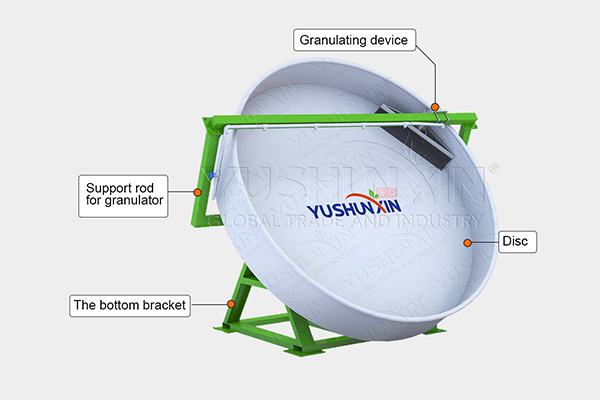

This Kenyans customer initially wanted to buy compost turner, crusher, granulator, drying machine, screener and packaging equipment with the capacity of 1 t/h. And he has experience in organic fertilizer production. So in order to continuously produce organic fertilizer, he wants a complete organic fertilizer production project. For this, we propose a solution for building a 1 t/h organic fertilizer disc granulation plant.

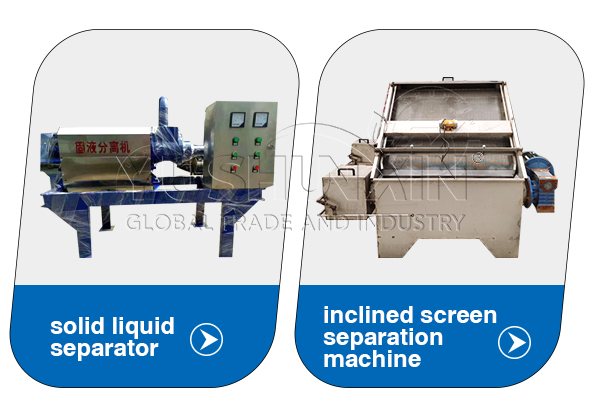

Machines for improving the quality of organic fertilizer granules

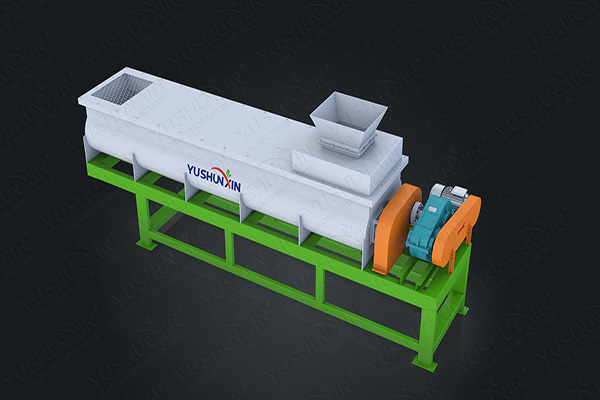

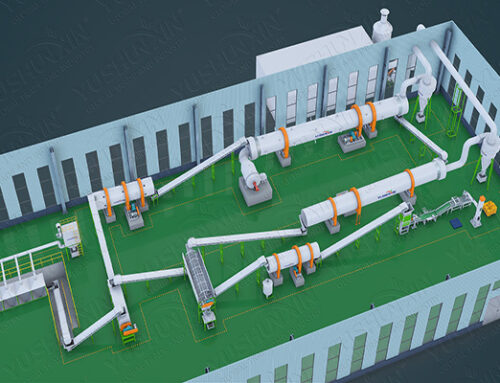

What is the design of a 1 t/h organic fertilizer disc pelletizer line?

When you want to setup an organic fertilizer disc pelletizer line, facory area are also two aspect you must consider. Usually, the whole organic fertilizer pellets making area is divided into three parts:

As the name suggests, this is an area for organic material composting. And generally, it will vary with capacity. The larger the capacity, the larger the composting area. For example, the customer from Kenya wanted to use windrow compost turner to prepare 1 tons of organic material compost per hour. You need to prepare an area of 300-500㎡. Can we make compost with a smaller space? Of course. You can select YSX organic fertilizer fermentation tank, which only needs 10-30㎡.

This area is designed for preparing organic fertilizer granules. You can install the equipment from feeder to packaging machine. For 1 t/h organic disc granulation plant, it needs about 1500㎡- 1700㎡.

Besides the above two areas, you also need to prepare a place for the final organic fertilizer storage. However, this area only needs a small area.

How much does it cost to build a 1 t/h organic fertilizer disc pelletizer plant?

Finally, the client from Kenya inquired about the quotation of the organic fertilizer disc granulator production line with a capacity of 1 t/h. Because of quality fertilizer equipment use, the price of it is $110,000-$140,000. Can I set up a 1 t/h organic fertilizer disc pelletizer plant in Kenya at a lower cost? The answer is yes. You can purchase this organic fertilizer disc granulation plant during our company’s promotional period, which will give you a discount. The price will also be more affordable. But the promotional time is limited, you still need to hurry up!

The above are details about our communication with the customer from Kenya. In addition, besides organic fertilizer disc granulation making line, we also can provide you with many other fertilizer manufacturing projects. Such as NPK fertilizer production line, compound fertilizer making system and cow dung powder fertilizer making line, etc.