For many farmers, ammonium sulfare pellets play an important role in improving capacity and quality of crop. But how to make high quality ammonium sulfare pellets? As a professional fertilizer equipment manufacturer, SX can provide you with suitable fertilizer production project. And we have many successful cases, for example: on 26th April 2023, a client from Romania inquired about ammonium sulfare pellets production for 15 tons/hour. The following are the details information in this case.

What is the layout of ammonium sulfare pellets production line?

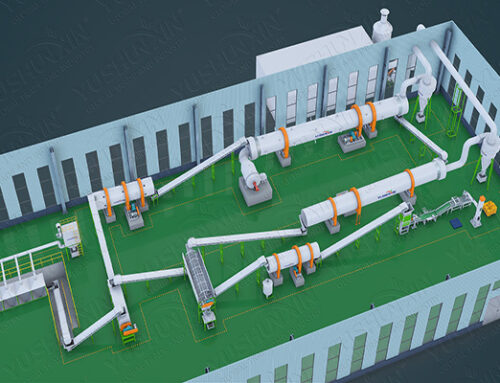

To help Romania customers to make ammonium sulfare pellets, SX can provide the layout.

First of all, the site can be divided into three areas: batching area, granulation area and packaging area. Then batching area includes batching machine, crusher and mixer for materials; granulation area includes granulator to pellets; packing area includes package machine. Plan the placement of equipment in different areas according to the equipment customers want to purchase. According to the customer’s output of 15 tons per hour, the total site area is about 1,500 square meters.

What granulation machine is suitable for ammonium sulfare pellets production?

How much does ammonium sulfare pellets making cost for you?

$300,000

Capacity of SX’s compound fertilizer production is about 1-40t/h. And different capacities have different price——$102,311-$1240,000. This Romania customer planned to prepare 100000tons of ammonium sulfare pellets a year. So he wants to know the quote of ammonium sulfare pellets production line. The price includes many factors, such as capacity, site, model,etc. For this, the quote of this production plant is about $300,000.

Our pricing plans

Can we manufacturing the ammonium sulfare pellets production line at a low cost?

The above is the details for making ammonium sulfare pellets with customers from Romania. In addition, apart from this production line, we can also provide you with other compound fertilizer production lines. For example, ammonium phosphate granular fertilizer making line. If you are interested in it, we can also give you a suitable fertilizer production project.