When you make cow manure into fertilizer, there is an item you must focus on. It is the moisture content of your manure material. In general, fresh cow dung has a water content of 70%-80%. But it is not suitable for organic fertilizer making, especially when you want to make organic fertilizer pellets. For example, on 23rd April 2023, a customer from Brazil inquired about cow manure dewatering machine. According to his requirements, we recommend our manure dewatering system. The following are the specific details of our communication in this case:

How Do you Get Dried Cow Manure through Solid-liquid Separator?

Customer from Brazil wanted to reduce the cow dung moisture content from 70% to 20%-25% that can get dried cow waste. For this, we recommend two fertilizer separator machine.

Cow dung drying machine can also help you get dried cow manure.

What is the Price of Cow Dung Dewatering Machine?

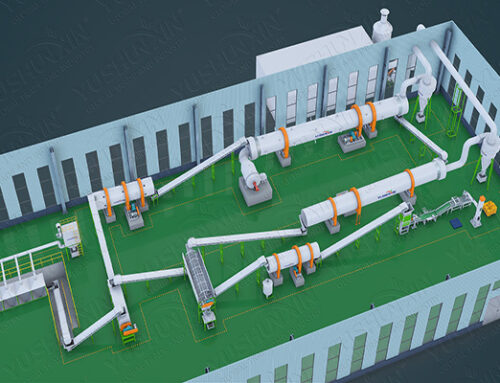

Then Brazilian customer also asked us the cow dung dewatering machine price. For this, on the one hand, the cost of cow manure separator depends on the selection of different types. Different types machines are suitable for different conditions of organic waste. On the other hand, the capacity of equipment also decides the cost. Compared with other companies, our greatest advantage is that we have our factory. That is to say, you can visit our factory to know more about and process, and we can provide customized service for you.

Why Do you Choose SX Cattle Manure Separator in Brazil?

Finally, client from Brazil wanted to know what advantages does SX have over other factories? As a manure dewatering screw press manufacturer, we focus on provide high-quality and efficient equipment for our customers. Therefore, you can rest assured of our equipment. In addition, we also offer different models to meet different requirements from different customers. In terms of equipment itself, it has the following advantages: