Can your machine produce compound phosphate fertilizer?

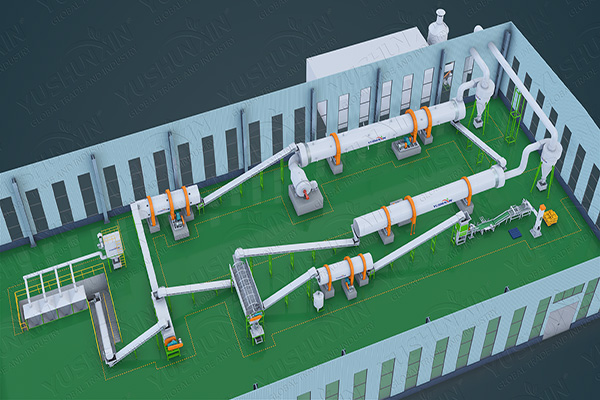

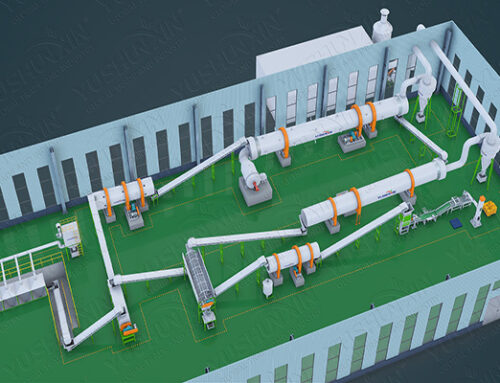

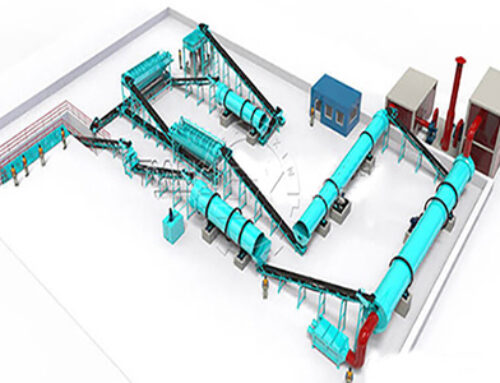

The customer from India wanted to make compound phosphatic fertilizer from MAP, Triple superphosphate and DAP. Our equipment is an excellent choice for processing them into fertilizer. Because our fertilizer equipment has high adaptability. It can be used in the compound fertilizer production of different concentrations and different scales. Even you want to make organic fertilizer, NPK fertilizer or BB fertilizer, we also can provide you with suitable fertilizer machines.

Which pelletizer you recommend for compound phosphate fertilizer making?

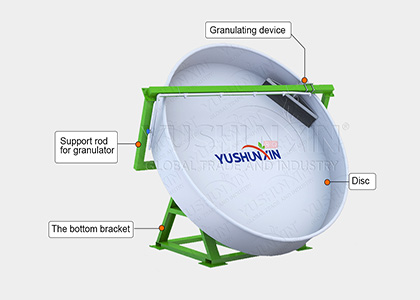

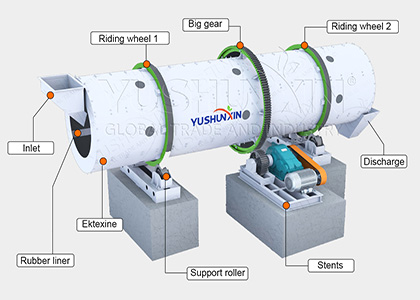

This Indian’s customer would like to make compound phosphatic fertilizer into granules. So he wanted to know which granulating machine is more suitable. In order to meet his requirement of compound fertilizer making, we offer you three types of pelletizer. Pan granulator, rotary drum granulating equipment and double rollers extrusion pelletizer.

What is the price of 500 t/d compound phosphate fertilizer making project?

The above are details about our communication with the customer from India. Expect compound phosphatic fertilizer production line, we also can provide you with many other fertilizer making lines. Such as NPK fertilizer production line, organic fertilizer production project, chicken manure composting system, etc. If you are interested in them, please contact us immediately.