How Do you Select the Ideal NPK Fertilizer Machine Manufacturer?

For arranging the investment cost of the NPK fertilizer plant, you should select the fertilizer equipment makers strictly. When selecting we suggest you consider it from three aspects. The details are as follows.

NPK Fertilizer Equipment Price

The fertilizer equipment price must be one aspect of your greatest concern. When selecting the NPK fertilizer production machines, you’d better compare the price from different fertilizer equipment factories. For example, the fertilizer granulation machine is over your budget. We recommend you to figure out why the price is high from the the machines performance and service.

The Quality of NPK Fertilizer Machine

Through the above, you can know the fertilizer machine price is related to its performance. Therefore, the quality of the machine is another factor which influences NPK fertilizer plant cost. You should the know about the composition materials of fertilizer making machine to measure the quality. Besides, you can also consider its working principle and structures.

Service for Buy SX ’s NPK Fertilizer Equipment

The service system can be a criteria when selecting the fertilizer equipment producers.You can consider it from aspects of the pre-sales, after-sales and deliver. What’s more, you should figure out whether they provide the technical support and on-site installation. These will directly affect the service life of your equipment. And it is related to whether your budget will increase.

What is the Cost of NPK Fertilizer Plant with Different Production Scale?

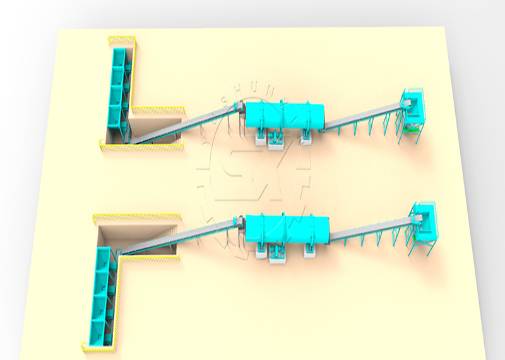

The different production scales of the NPK fertilizer plant will have the different budget. According to our years of experience, we can divide the production scale into two ranges of 1-10t/h and 10-20t/h. The following content can be your references.

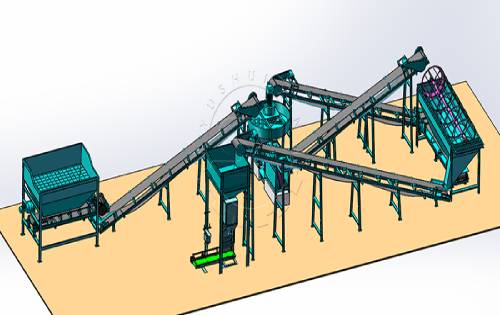

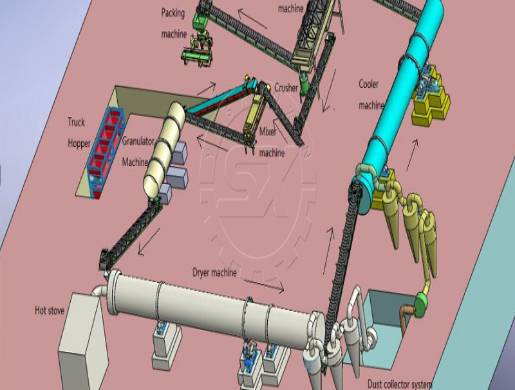

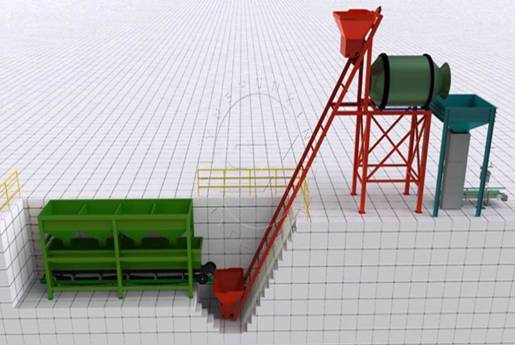

In general, this system contains dynamic batching machine, cage crusher, double shafts horizontal mixer, double roller granulator or pan granulation and packing equipment.

How to Choose the Right Production Site for Reducing the NPK Fertilizer Plant Cost?

The selection of the production sits will also affect the NPK fertilizer plant cost. For example, you choose the production site which is far away from the raw materials supplier. And the transportation charge will be increased. Therefore, you need to consider many aspects while selecting the production sites. You can refer to the following.