Under the aegis of government policy of production, market, training and related systems. The animal breeding farms have a prosperous development in the Lebanon. But with the selling of animal meat, there is an item that needs to focus on. How to dispose of animal waste in farms? On 20th March 2024, a customer from the Lebanon contacted us for an environmentally friendly way to treat cow dung in the farm. And there are about 1,000 cows in his farm, And finally, he chose a small scale commercial fertilizer composting system. The following are the specific details of our communication in this case:

What equipment is suitable for small scale compost production?

After a period of consideration, the client from the Lebanon chose to process cow dung into compost first. And because this Lebanese customer has told us that there are about 1,000 cows in his farm. The small scale compost machine is the best choice for him. Then what equipment is suitable for starting commercial fertilizer composting on a small scale? There are four types of SX compost machines for your reference.

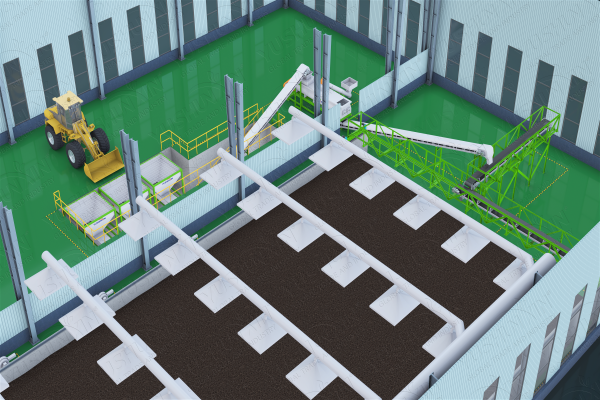

Groove type compost turner

The groove type compost turner is a typical equipment for starting cow manure fermentation in trenches. During fermentation, it will move along the rails on both sides of the fermentation trench and the stirring teeth will rotate to turn the materials in grooves. This will create a suitable environment for cattle litter fermentation. So the manure can be fermented into compost quickly and easily. This machine can work for fermentation grooves with a width of 2-5 m and a depth of 1-2 m. It is popular with small scale compost fertilizer plants.

Chain plate type composter

Chain plate type composter is another equipment designed for small scale composting in trenches. Compared with the above compost equipment, it can make cattle litter contact with oxygen for a longer time. Because of the design of the alloy pallet, which looks like a conveyor belt. In addition, it adopts variable frequency speed control system, which make it well adapt to the regulation of working load, It has a turning span of 3-4 m and can process material with a height of 1-2 m.

Windrow compost equipment

If you want to directly to compost cattle litter on the ground in a small scale, windrow compost turner is an is ideal choice. And it is advisable to finish it on the cement floor, which can prevent sewage from seeping into the ground. Using this composter, you need to pile cattle poop into long windrows. Then drive moving type or crawler type composter to straddle over the material windrows to mix it. This machine can help you greatly reduce the cost of organic waste fermentation on infrastructure and human powder, Moreover, its capacity can reach 300-500 m³/h.

Horizontal organic fertilizer fermentation tank

However, if you don’t have a enough space for manure small scale commercial fertilizer compost, you can choose horizontal fermentation tank. It is a kind of in-vessel compost equipment, which starts organic fertilizer fermentation in a closed environment. And the whole horizontal fermentation pot only occupies an area of 10-30m³, which is far less than that of other cow dung composters. And it is an environmentally friendly compost machine. Because it has a gas waste treatment system, which can reduce the pollution generated in composting.

How much does small scale compost production cost?

Finally, the customer from Lebanon wanted to know that how much does small scale compost production cost. To be honest, the price of small scale compost system is not fixed all the time. Because it is closely related to capacity, equipment types, configuration and even time. But for reference, a whole set of small scale compost production line including composter, batching machine, mixer, and conveyor, needs about $ 5,000 -$ 15,000. If you want to get more precise quote, welcome to contact us immediately.