In Thailand, NPK compound fertilizer plays an important role in agricultural development. So many businesses invest in chemical fertilizer manufacturing, especially NPK compound fertilizer production. But how to prepare NPK compound fertilizer using compaction? You can setup a NPK compound double roller granulation line. For this, you need professional fertilizer machines and design. SX can help you a lot and there are many successful cases. For example, on 9th March 2023, a customer from Thailand inquired about NPK compound fertilizer making machines. The following are the specific details of communication in this case.

Which granulation machine is suitable for NPK compound fertilizer making?

The client from Thailand wanted to use Urea, AS, DAP, MAP and MOP to prepare NPK fertilizer pellets. So first of all, it is essential to buy a type of suitable chemical pellet making equipment.

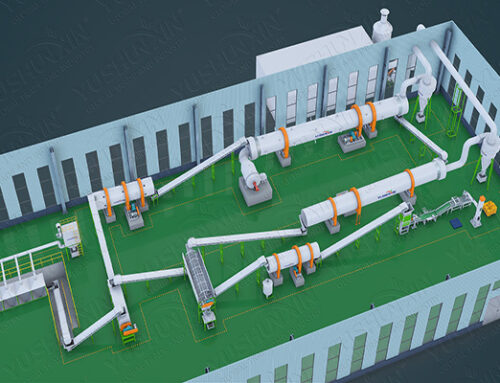

How to further process NPK compound fertilizer after double roller granulation?

Finally customer from Thailand wanted to improve quality of pellets after compaction granulating. So we recommended him screener, polishing machine, coating equipment and automatic packaging machine. If you want to produce high quality NPK compound fertilizer pellets, these fertilizer machines you can use to further process NPK compound fertilizer after compaction granulating. For example: