On 27th December 2023, there is a drum coating machine delivery to Thailand. It will be transported to the customer who plans to produce high quality fruits with using good fertilizer. This Thai client wanted to coating their NPK, urea and ammonium phosphate prils fertilizers in order to extend their release time. For this, he inquired us some questions about coating equipment and process. And we provided him with a professional fertilizer coating machine. The following are the details of this case:

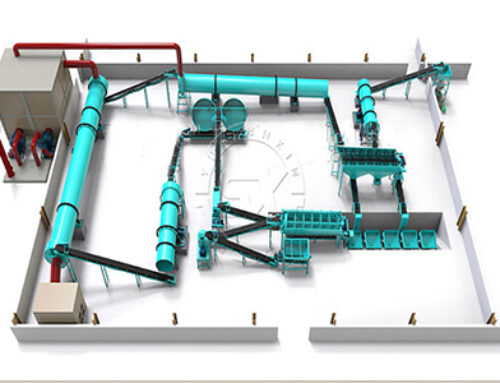

What scale drum coating machine can you choose in SX?

Because the customer from Thailand planned to coat fertilizers in the first phase production with the capacity of 400t/d, what scale drum coating machine is suitable for him? There are two scales for your choice.

Large scale fertilizer coating machine for sale

According to the capacity of 400t/d, working 20 hours a day, this customer needs 20t/h fertilizer coating machine. For this, SX specially designed a suitable drum coating machine for you. It can coat 15-30 t/h pellets with BM 1800*8000. In addition, we can also provide you with 7-15 t/h fertilizer coating equipment as a alternate option.

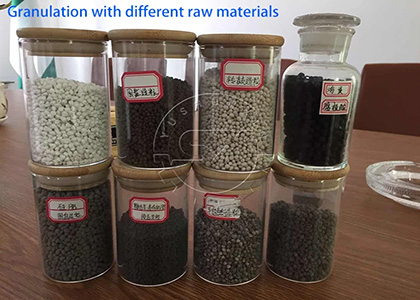

What materials are suitable for coating pellets?

In order to have high quality fruit, the customer from Thailand need to prolong the release time of fertilizer. But it is related to coating materials. So there are two types of materials for coating pellets. So the details are as follows:

For your reference, it is not true that a kind of fertilizer coating agent is suitable for all kinds of pellet fertilizers. So if you want to start your fertilizer business, you should find suitable coating material according to the ingredients of the fertilizer you’ll produce.

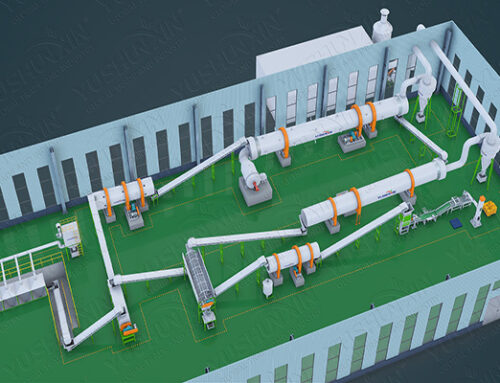

How does fertilizer coating machine work to extend fertilizer release time?

This Thai client wanted to know the process of coating fertilizer. So our engineer explained him:

The granular fertilizers enter into the rotating part of the fertilizer coating drum machine from the feeding port. And then they will rotate along with the drum part. Near the discharge port, there is a sprinkling device, in which you should put the fertilizer coating agent. When the fertilizer pellets move to the sprinkling device, the prepared oily or powdery coating agent will be sprayed on the surface of the granule fertilizers. Finally, the machine will discharge coated fertilizer pellets into the next process.

Why do you choose SX fertilizer coating machine?

Thai client told us that he compared many companies and finally chose us. Why?

Besides drum coating machine, SX can also provide you with many other auxiliary machines for organic or chemical fertilizer production. Including crusher, mixer, screening equipment, packaging scale, etc. If you are interested in them, welcome to contact us immediately.