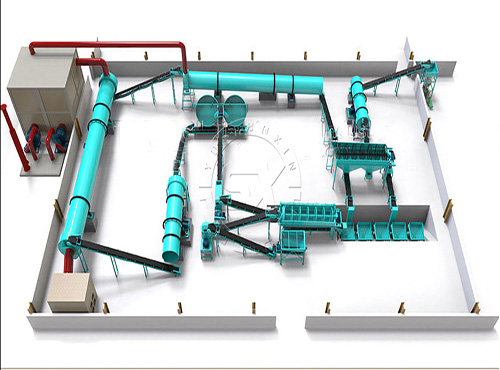

Compound NPK Fertilizer Production Line

There are two granulation methods can produce compound fertilizer with different fertilizer equipment. Wet granulation process and dry granulation method. They have different production principles to make high quality compound fertilizer. Now, let SX fertilizer machine engineer introduce them.

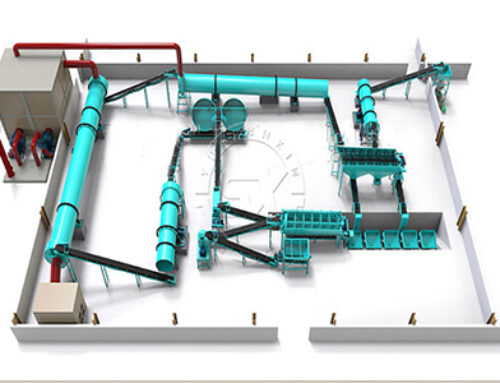

NPK Fertilizer Wet Granulation Plant

Why do you choose this granulation process to make compound fertilizer?

Then how to produce NPK compound fertilizer and what equipment you can use?

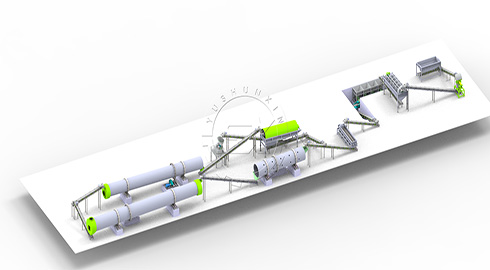

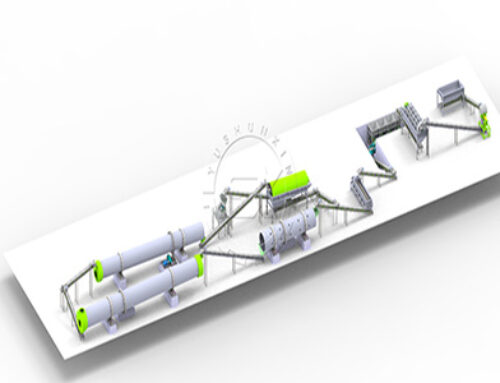

Coating equipment

Then coating equipment will add a protective film to prevent moisture absorption and nutrients loss.

Automatic packaging machine

Finally, packing finished compound fertilizer by automatic packaging machine.

This is the whole process of complex fertilizer production with wet granulation method.

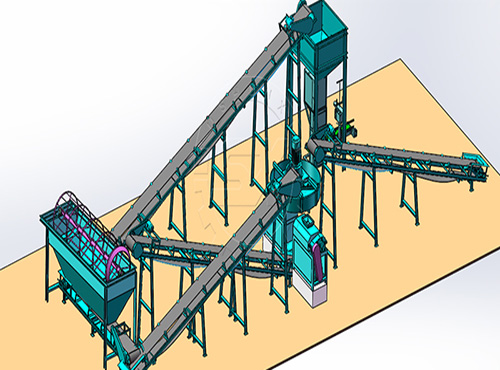

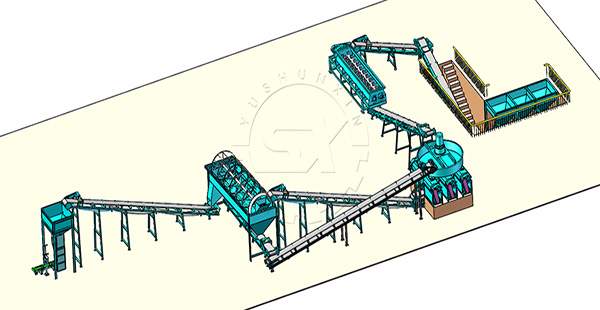

Compound Fertilizer Dry Granulation Manufacturing Line

Some customers consider the cost and moisture of making compound fertilizer. For this, compound fertilizer dry granulation manufacturing line is the best option for you.

Compound fertilizer dry granulation line, as the name suggests, there is nearly no water involved during this process of compound fertilizer manufacturing. For one thing, the chemical material has a low moisture content of below 10%. For another, it doesn’t need water in the process of granulation. Double roller granulator is an ideal choice for dry granulation of compound fertilizer. It mainly turns chemical powder into granules by extrusion of two rollers. There is only physical force and no chemical reaction.

As mentioned above, there is nearly water needed in the compound fertilizer dry granulation line. So it also doesn’t need to buy drying machine and cooling equipment to reduce exceed moisture. This can help you reduce costs on equipment, factory rent and energy consumption. So you can produce compound fertilizer at a lower cost.

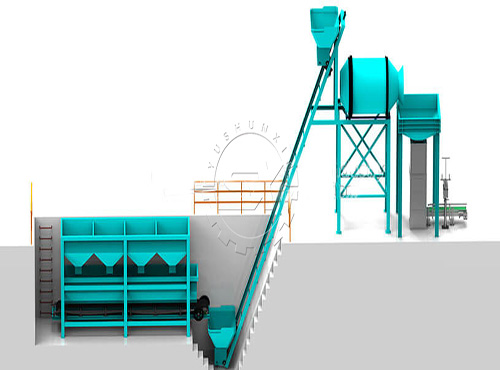

BB Compound Fertilizer Making Line

Compared with the above production line, this BB compound fertilizer production line has more benefits.