Drum granulator is a kind of granulation equipment commonly used in the production of compound fertilizer, organic fertilizer, biological fertilizer, controlled release fertilizer and other fertilizers. Moreover, it is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. Then the main working method belongs to aggregate wet granulation.

Therefore, having a rotary drum granulator fertilizer production line can bring you equipment with large output, high pelleting rate and stable operation. If you want to know its related raw materials and other information, please see the detailed introduction below.

Raw material for rotary drum granulator production line

The rotary drum granulator fertilizer production line can produce both organic fertilizer and compound fertilizer. But from its performance, it is more suitable for producing large-scale compound fertilizer. Below I will introduce its raw materials from two aspects.

Compound Fertilizer

The drum granulation production line is aimed at the compound fertilizer, the most important thing is the pre-batching aspect. If the ingredients are not properly grasped, even if producing the granular fertilizer later, it will not be able to achieve the desired fertilizer effect. Then common raw materials are urea, dap, mop, kcl, tsp, ssp, ammonium sulfate, phosphate, gypsum, lime or other materials. These raw materials are proportioned according to the ratio. And you can also add some bacterial agents. Finally, you can produce granular fertilizers with high nutritional value .

Organic Fertilizer

The drum granulation production line is also suitable for organic fertilizer. Raw materials for organic fertilizers are relatively common, including organic waste such as peat, sludge, chicken manure, livestock and poultry manure, sugar filter sludge, and papermaking sludge. The cost of these raw materials is relatively low, but they can play a great role. For organic granular fertilizers,the most critical thing is not the early stage, but the granulation part. Therefore, the granules produced by the drum granulator can achieve the final desired effect.

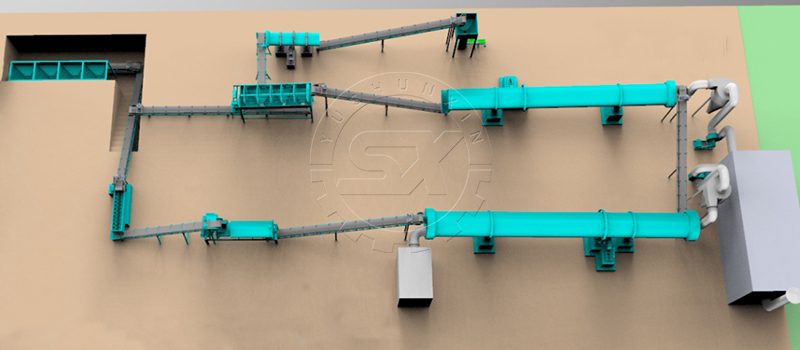

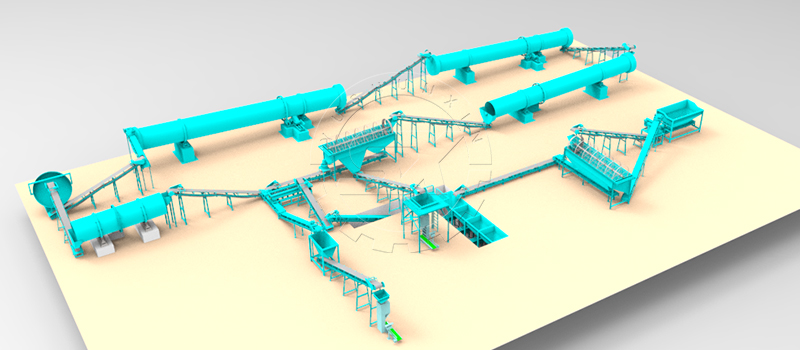

The process flow of the rotary drum granulation production line with fertilizer nitrogen, phosphorus and potassium content of 20-48%

If you want to produce good granular fertilizer, you must understand the production process of your production line. The following is a detailed introduction to the production process of the rotary drum granulator fertilizer production line.

Rotary drum granulation machine that wins customer in your plant

The core equipment in the drum granulation production line is the drum granulator. Only when configuring this equipment properly can the particles produced achieve the effect you want. So, below I will introduce the benefits that this device can bring to you for your reference.

The following is a detailed introduction to the link process and the corresponding common equipment introduction.

The rotary drum granulation production line with a granulation rate of 90%

In order for the drum granulation production line to exert its maximum effectiveness, you need to select the core equipment – the drum granulator properly.

Our company’s drum granulation machine uses the high-speed rotating mechanical stirring force and the resulting air force to continuously mix,granulate, spheroidize, extrude, collide, compact, polishing fine powder materials in the machine, and other processes to achieve the purpose of granulation. The shape of the particles is spherical, the sphericity is ≥0.7.The particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. If you want to adjust the particle size, you can adjust it appropriately through the mixing amount of materials and the spindle speed. Generally, the lower the mixing volume, the higher the speed and the smaller the particles.

How does the drum granulation production line improve the granulation performance?

The quality of granulation performance is the key to determine the drum granulation production, how to improve granulation performance?

The time and frequency of material rolling in the granulator determine the prime factor of ball forming rate and particle roundness. The higher the rolling frequency and the longer the time within a certain period of time, the higher the ball forming rate, and the rounder the particles will be after balling.

Tips: If the internal surface finish of the drum granulator is large, the friction between the material and the cylinder wall will be reduced. We can solve it by adjusting the speed of the granulator and installing a small lifting board inside.

Stable material volume and uniform liquid phase distribution in the drum granulator are the keys to produce qualified granules. During the granulation process, you can add water appropriately to make the granules more viscous, but it is difficult to form agglomerates due to uneven distribution of the liquid phase of the material when spraying is uneven. At this time, we can increase the spraying device to increase the wetted area of the material.

A reasonable material structure is the basis for improving the ball forming rate. Reasonable material structure mainly refers to:Reasonable collocation of raw material fineness. Reasonable collocation of sticky material and sandy material. Consider the chemical reaction between materials (free water, hygroscopicity) when formulating. The comprehensive moisture content of the mixed materials. And a reasonable amount of returned materials (the experience value is generally 30% to 40%).