17:17:17 NPK fertilizer production line is a kind of compound fertilizer production line. It can help you produce high quality NPK fertilizer. And there are two hot sale NPK preparation plans in SX machine factory. They are NPK fertilizer granulating line and NPK bulk blending line. Whether your budget is enough or not. Whether you want to make NPK fertilizer by wet or dry granulation method. They can fully met your needs. If you have any special requirement, you can contact us for customization.

Top 2 NPK 17:17:17 fertilizer production lines for your choice

In order to meet customer’s requirements, our engineers design two NPK 17:17:17 fertilizer making lines. 17:17:17 NPK fertilizer granulation plant and 17:17:17 NPK fertilizer blending system. They use different methods and fertilizer machines to produce NPK fertilizer. You can choose one according to your needs.

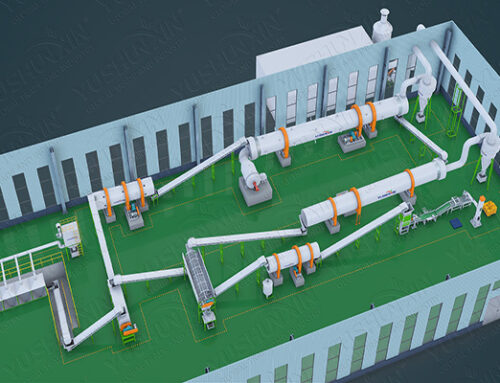

17:17:17 NPK fertilizer granulating line

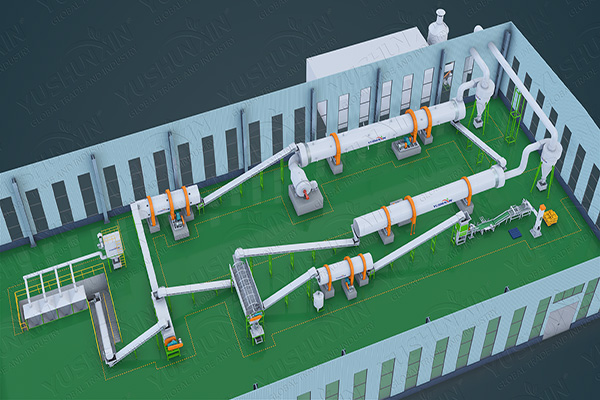

If you want to turn powdery materials into NPK pellets, this fertilizer production line is an optimal choice. During this process, the materials will go through multiple processes. Including batching, crushing, mixing, granulation, drying, cooling, screening, coating and packaging. They will make powdery materials become the high quality granular 17:17:17 NPK fertilizer you need.

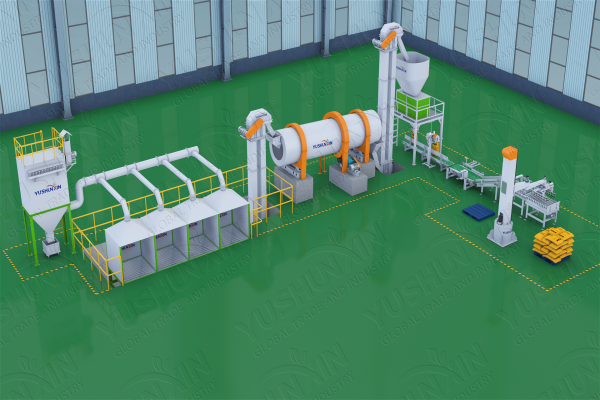

NPK 17:17:17 fertilizer blending line

But if you don’t have enough budget, we recommend you to choose 17:17:17 NPK fertilizer blending line. It is also known as a bulking blending production line. 17:17:17 NPK pellet mixing line is designed for processing granular materials. Batching, mixing and bagging, only 3 steps, you can get high quality industrial 17:17:17 NPK. Simpler process means less space occupation and fewer NPK fertilizer machines employment. So you can start 17:17:17 NPK fertilizer preparation at a lower cost. Can it produce NPK fertilizer in large scale? Of course, the largest capacity of our NPK bulk blending line can reach 40 t/h. Moreover, whether you want to prepare 17:17:17 or 20-10-10,it can fully meet your needs.

What granulator is suitable for making 17:17:17 NPK fertilizer granules?

When you want to make 17:17:17 NPK fertilizer pellets, a suitable granulator is important. Whether you prepare to produce small scale granules or large scale pellets, we can both meet your requirements.

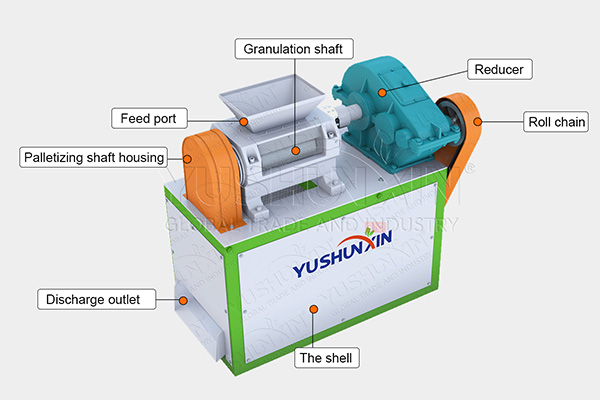

Small scale 17:17:17 NPK fertilizer pellets making

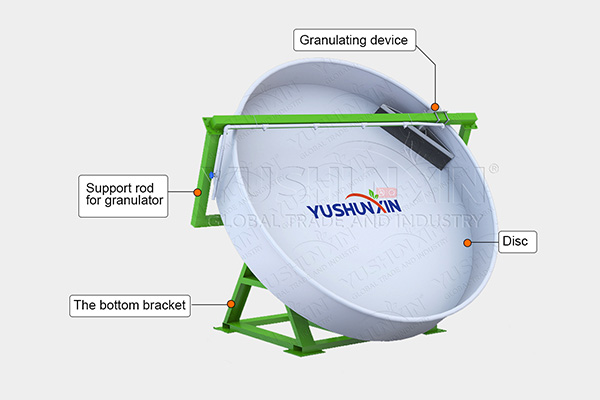

If you prepare to make small scale 17:17:17 NPK pellets, double roller granulator with dry granulation and disc granulation machine with wet granulation are the best choices for you. And extrusion machine can produce 1- t/h 17:17:17 NPK granules and pan granulator can make 1-6 t/h. What’s more, their granulation rate can reach over 93%. They can both meet your needs for producing small scale NPK fertilizer pellets.

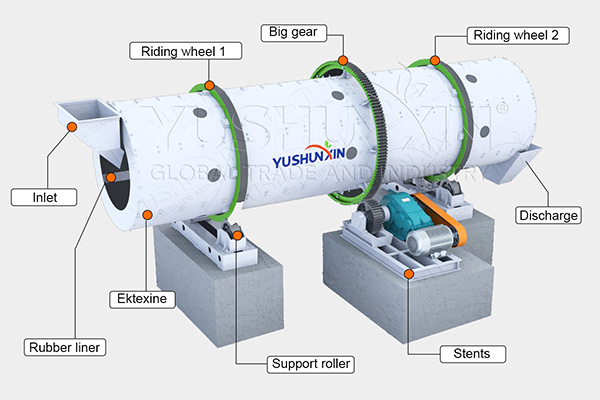

Large scale 17:17:17 NPK fertilizer granules production

For large scale 17:17:17 NPK fertilizer granules production, we recommend you with rotary drum granulation machine. It can make 1-30 t/h NPK pellets with wet granulation method. So you need to dry and cool the final product after granulation. And this equipment has many types of designs. Such as rubber lining, stainless press stripes and cleaning holes.They can all help you finish 17:17:17 NPK fertilizer granules production.

How to improve the yield of 17:17:17 NPK fertilizer pellets by using SX fertilizer equipment?

If you want to improve the yield of 17:17:17 NPK fertilizer pellets, we can provide you with some suitable SX fertilizer equipment—rotary drum and disc granulation two-in-one production line. This type of plant includes rotary drum granulation machine and disc pelletizer. So it can make high quality 17:17:17 NPK fertilizer granules.