Rotary drum granulator is a machine which can turn granulate materials into specific shapes. It is suitable for large scale production of cold and hot granulation. What’s more,it is one of key facilities to make compound fertilizer. You can allocate other machines to form a complete compound fertilizer production line. In addition,we have many years of the fertilizer equipment production experience. Therefore, you can trust that we can provide you with quality rotary drum granulation machine at fair price.

What Additives Can Be Used in Drum Granulation Fertilizer Manufacturing?

During the granulation process, in order to increase the viscosity of the granules, improve the granulation efficiency and agglomeration rate. You can add some binders appropriately to improve the physical properties of the granules.

How Does Rotary Drum Granulator Works?

Its working method belongs to wet granulation. Through a certain amount of water or steam, the raw materials are fully chemically reacted after the humidity is adjusted in the cylinder. Under certain liquid phase conditions, with the help of the rotation of the cylinder, the material particles generate extrusion force to agglomerate into balls.

Why should you choose the fertilizer rotary drum granulation machine?

There are many advantages of the drum granulator. You will not regret it if you choose this equipment under the premise that it is suitable for your production line.

How to reduce the cost of granulation and avoid waste of raw materials?

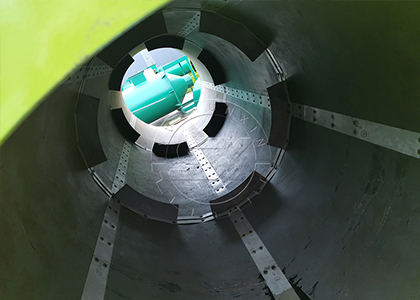

Since the working principle of the drum granulator belongs to wet granulation, the wet raw materials are easy to stick to the inner wall of the drum. This greatly affects the granulation rate of the equipment. Although the lining is made of rubber to avoid a large amount of fertilizer from adhering to the equipment, we have designed multiple cleaning holes on the granulation drum to maximize cleaning efficiency. During the production of granular fertilizer, with the rotation of the drum, the hammer hits the holes by gravity, and vibration shake off the raw materials on the wall. In this way, you can avoid the problems of large waste of raw materials and low granulation rate effectively. And you can reduce the maintenance cost of the machine .

Auxiliary machines you can use with our drum granulator in production line

If you want the granulation to meet your expectations, then you cannot ignore some equipment on your drum granulation production line.

The Guidance of Fertilizer Granulation Drum Installation Procedure

The right installation procedure is the prerequisite for the smooth and stable operation of our rotary drum granulating machine. Hence, just follow the step below after the arrival of our rotary granulator machine in your fertilizer making plant.