What Aspects Should you Pay Attention to During Aerobic Fermentation?

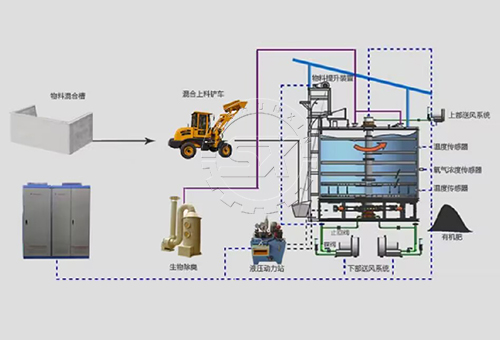

In the process of aerobic fermentation, temperature, oxygen, and humidity will all change, and these three aspects deeply affect fermentation.

In addition, in the upper part of the in-vessel composter, you can also install a heating device. This device heats the oxygen pressurized into the tank to ensure the proper temperature for the fermenter.

Oxygen

Oxygen is the most important thing, without enough oxygen, aerobic fermentation cannot take place. You can press the heated oxygen into the tank through a high-pressure Roots blower to ensure that the aerobic bacteria have enough oxygen. An oxygen sensor also monitor the oxygen concentration in the tank.

Humidity

The moisture of the material before and after entering the organic fermentation tank is different. And achieving a good state of fertilizer production through equipment adjustment. Therefore, the moisture of the feed material is 50-60%, and the moisture of the output material after successful fermentation is about 30%.